Karl Mayer’s tricot machine has its sights set on delicate apparel fabrics

Innovative Karl Mayer warp knitting drives new trends in home textiles for the coming season.

7th January 2026

Knitting Industry

|

Obertshausen, Germany

Warp knitted fabrics are proving to be versatile all-rounders in home textiles, offering designers wide creative freedom and manufacturers strong commercial opportunities. From bedding and mattresses to curtains, upholstery and terry towelling, warp knits enable the development of fashionable designs and continually new products.

Among the latest developments are super-soft blankets with a silk-like appearance and handle yet priced at conventional mid-range levels. Designed for warm summer nights, these blankets offer a Q-max value of 0.24 W/cm², indicating a distinctly cool feel on the skin. The bedding is also breathable, easy to wash, quick drying and crease resistant.

The blankets are based on a carefully engineered warp knitted fabric. The cover textile surrounding the filling layer is made from bright polyamide and elastane and produced on an HKS 2-SE in gauge E 36. It is extremely dense and smooth surface enhances the gentle sheen of the polyamide while delivering a cooling sensation, with elastane providing stretch and suppleness. High-speed production on the HKS 2-SE also ensures economic efficiency, with the machine adaptable to standard blanket sizes.

Warp knitted corduroy is also gaining renewed attention in home textiles. Ribbed structures are reappearing in cushions, blankets and furniture covers, created through specific threadings and equal-length underlaps that are cut and brushed after knitting. Variations range from classic striped corduroy to wide or narrow ribs and even faux fur effects for cosy blankets. Creative underlap designs allow for distinctive looks such as turtle velvet patterns, where square segments are arranged in an offset layout.

These corduroy fabrics can be produced efficiently on the HKS 3-M, one of the most flexible machines in the Karl Mayer portfolio. In addition to corduroy, it produces velour and cuddly blankets, terry towelling, cleaning textiles and fabrics for automotive interiors, sportswear and technical applications.

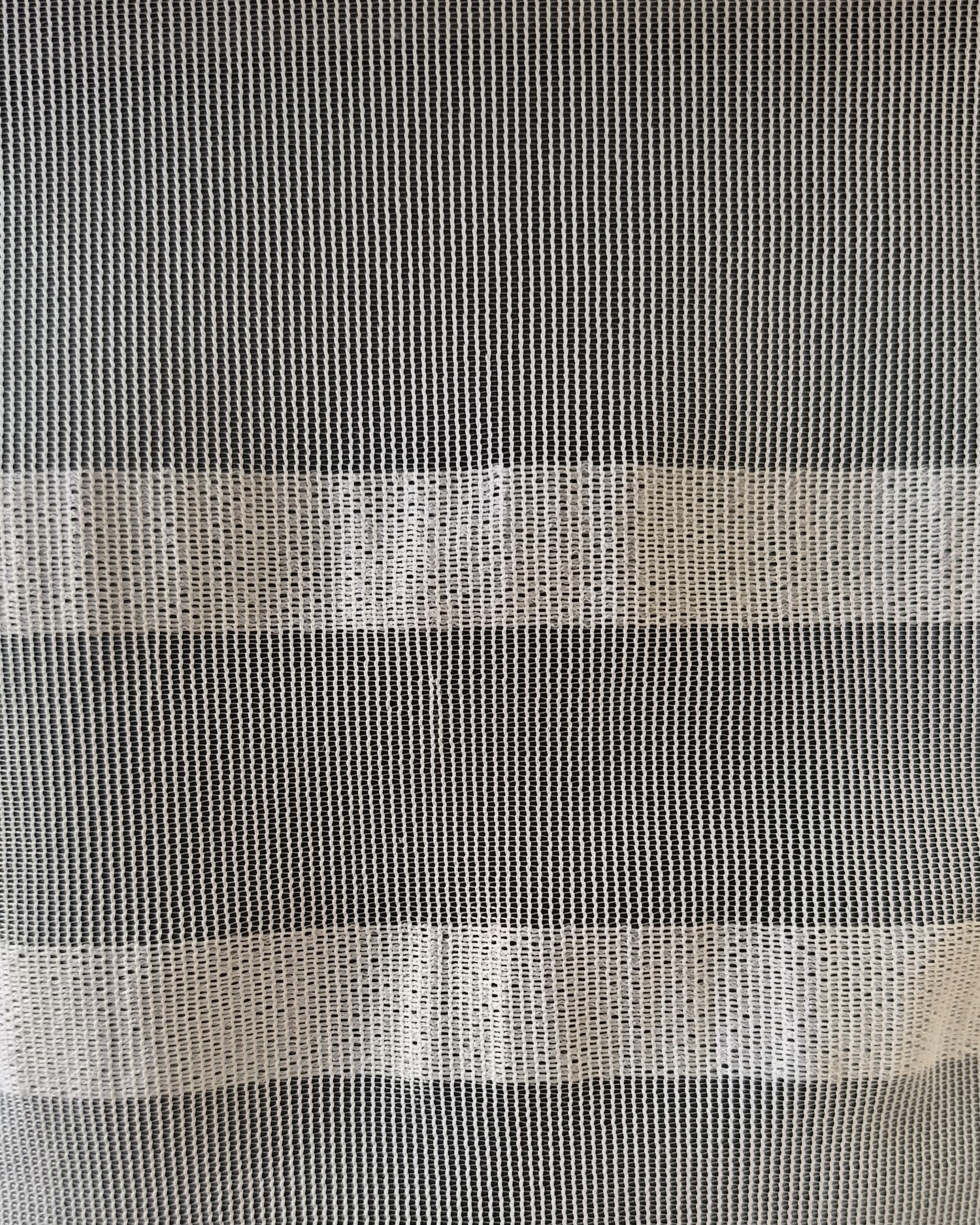

Warp knitting is also demonstrating its potential in window decoration. A new curtain collection featuring fancy stripe patterns has been produced on a TM WEFT in gauge E 24. Striped sections of varying widths and densities are created through changes in weft repeat, stitch density and the use of effect yarns. Following a machine upgrade in 2024, production speeds are now 20% higher, offering an attractive alternative to traditional weaving.

Karl Mayer will showcase these possibilities during Heimtextil, inviting visitors to its Obertshausen site near Frankfurt am Main, where specialists and selected machines will be available for discussion and live demonstrations.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more