Groz-Beckert Webinar: Ultra-fine knitted fabrics

Ultra-fine circular-knit fabrics are still a very important trend. So, which yarns are best suited to them? Our earlier Focus on Ultrafine Circular-Knit Fabrics article by Groz-Beckert (Groz-Beckert Online Newsletter second edition 2010) published in October 2010, reported on the properties and potential applications of ultra-fine knitted fabrics, from knitting all the way to sewing that meets precise requirements. Here Groz-Beckert advises on how to choose the right ya

18th March 2011

Knitting Industry

|

Albstadt

Ultra-fine circular-knit fabrics are still a very important trend. So, which yarns are best suited to them?

Our earlier Focus on Ultrafine Circular-Knit Fabrics article by Groz-Beckert (Groz-Beckert Online Newsletter second edition 2010) published in October 2010, reported on the properties and potential applications of ultra-fine knitted fabrics, from knitting all the way to sewing that meets precise requirements. Here Groz-Beckert advises on how to choose the right yarn for the job:

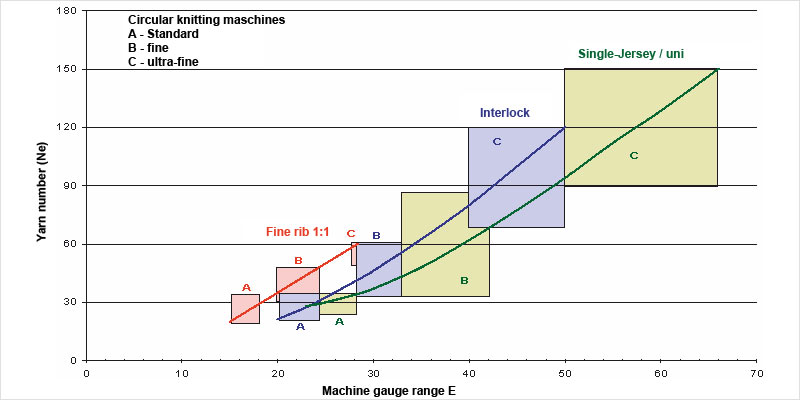

In principle, filament yarns in the count range dtex 22 to 50 are an economically efficient alternative for production on circular knitting machines with high gauges. Spun yarns made from cotton and cotton mixes are often required by the market because of their special textile properties. The diagram below shows very clearly the yarn counts (Ne) required for spun yarns, in relation to the knitting machine gauge range (E). It is clear that for ultra-fine machine gauges of E50 to E66, spun yarns of Ne 90 to Ne 150 are required.

The spinning of ultra-fine yarns like these requires very fine, extra-long-staple cotton fibres with an average fibre length of approximately 1 ¾ inches (44.5 mm). With a single-fibre linear density of 1.22 dtex, and with yarn number Ne 150, just 33 fibres are theoretically available in the yarn cross-section. Such long-staple types of cotton come for example from Peru (Pima) or Egypt (Giza).

The right raw material is not enough in itself, however, because it is only by making full use of the complete fibre length that the finest count cotton yarns can be produced. The shorter fibres are removed in the combing process. Three methods of spinning can still be considered: the classic ring spin method, the compact spinning method and the air spinning method, also known as the air jet spinning method.

“If you need to know more about optimal yarn selection, our experts at Groz-Beckert will be happy to assist you,” the company says.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more