Beverly Knits expands operations

Covered yarns specialist ContiFibre is introducing a new range of products made from polymer with corn based Bio-PDO from DuPont. In close cooperation with Advansa in spinning and DuPont in polymer development the new yarns are targeted at producing more environmentally friendly microfibre for circular knit applications. The new yarns are to be branded Biophyl(r) and are made with Sorona(r) PTT, a special polyester-like polymer where the oil based Glycol

5th November 2008

Knitting Industry

|

Casaloldo, Italy

Covered yarns specialist ContiFibre is introducing a new range of products made from polymer with corn based Bio-PDO from DuPont. In close cooperation with Advansa in spinning and DuPont in polymer development the new yarns are targeted at producing more environmentally friendly microfibre for circular knit applications.

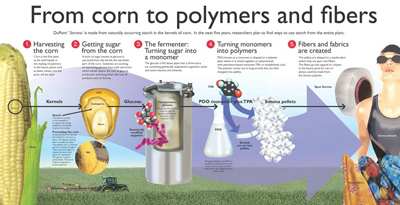

The new yarns are to be branded Biophyl(r) and are made with Sorona(r) PTT, a special polyester-like polymer where the oil based Glycol component has been replaced with Bio-PDO(r) made from corn sucrose. In addition to a renewable raw material and reduced dependency on petro-chemicals the polymer production is also extremely efficient, with 30-40% less energy consumption and 50-60% less greenhouse gas emissions than traditional Nylon 6 polymer.

According to ContiFibre’s Andrew Venables, Biophyl(r) fabrics are easy-care and have both improved softness and elasticity when compared to conventional polyester due to the unique semi-crystalline molecular structure. Venables told KnittingIndustry.com: “Biophyl(r) fabrics can also be dyed at lower temperatures than conventional polyester with full colour depths and outstanding wash fastness being achieved at 110°C.”

ContiFibre is situated in Casaloldo in the province of Mantova and the centre for European ladies hosiery production. At this site ContiFibre has its main headquaters, the ContiFashion development centre and a large production facility using a wide variety of processing routes. The company also has production facilities in Italy, France and UK and a distribution company in Poland.

Situated in the picturesque Ardeche region of France, ContiFibre S.A. is the groups largest texturising operation where a modern facility uses the latest texturising technologies to produce the highest quality products at competitive prices for customers world-wide.

Purchased in 2001 from the Sara Lee Corporation, the ContiFil plant is the conventional covering operation for the group. The facility was built in 1990 and has 100 covering machines running the highest quality single and double covered yarns for a variety of textile applications. The plant is situated in Lendinara in the province of Rovigo in the North East of Italy.

Purchased in 2002, ContiFibre UK is situated in the city of Macclesfield, the historic centre for silk production in the UK. In addition to a modern texturising facility the plant has the group’s largest twisting plant for the production of speciality yarns for lace, narrow fabrics and industrial applications.

The latest acquisition to the group, ContiFibre Poland is a distribution company based in the textile city of Lodz in Poland and is the exclusive distributor for both Lycra and ContiFibre produced products to this important textile market

ContiFibre only started producing yarns in 1990 serving the local ladies hosiery industry in the Castelgoffredo area of Italy. With sales of more than 100 million euros per year, ContiFibre is a key supplier to many of the world’s leading textile companies, brands and retailers.

Biophyl(r) is a trademark of Advansa Marketing GmbH

DuPont(r) and Sorona(r) are trademarks of E.I. DuPont de Nemours and Company, Inc.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more