Carpi date for ultrafine WHOLEGARMENT technology

Leading computerised knitting machine manufacturer Shima Seiki of Wakayama, Japan, will be exhibiting at the 11th Dhaka International Textile & Garment Machinery Exhibition (DTG 2014) in Dhaka, Bangladesh that will take place from 12-15 February 2014, in cooperation with its partner Pacific Associates. Operating within the Bangladeshi market since 1996, this will be the seventh time the Japanese manufacturer will participate in the exhibition.

30th January 2014

Knitting Industry

|

Wakayama

Leading computerised knitting machine manufacturer Shima Seiki of Wakayama, Japan, will be exhibiting at the 11th Dhaka International Textile & Garment Machinery Exhibition (DTG 2014) in Dhaka, Bangladesh that will take place from 12-15 February 2014, in cooperation with its partner Pacific Associates.

Operating within the Bangladeshi market since 1996, this will be the seventh time the Japanese manufacturer will participate in the exhibition.

As strong candidate for China-Plus-One manufacturing, Bangladesh has seen a significant increase in knit production for export purposes in recent years. At the same time, buyers are demanding quicker turnaround for orders with more variety, the company reports.

Adding to that the current demand for higher wages and improved working conditions, a formula is created for major transfer of technology from manually operated knitting machines to computerised knitting machines.

Shima Seiki’s intarsia specialty machine MACH2SIR is said to offer high productivity. With 40 intarsia carriers, MACH2SIR features the largest number of intarsia feeders available.

Maximum knitting speed of 1.4 metres per second in combination with the new R2CARRIAGE System dramatically improves efficiency and productivity in intarsia production, the company reports.

The previously existing problem of programming for knitting with so many intarsia carriers is now solved with the latest automatic yarn carrier setting software on SDS-ONE APEX3 design system.

Featuring Shima Seiki’s original SlideNeedle, SCG122SN is a computerised knitting machine specialising in the production of coarse gauge knitwear.

In addition to such priorities as speed, efficiency and consistent quality, market demand reveals that the computerisation of traditionally hand-knitted low-gauge knitwear must place additional emphasis on fabric texture and feel. The SlideNeedle is said to help to achieve that by allowing the SCG122SN 3 gauge machine to produce knitwear with robust, handcrafted texture ranging from 2 to 4 gauge.

SSR112 is Shima Seiki’s most affordable model. High productivity is achieved with a maximum knitting speed of 1.2 metres per second, as well as with the R2CARRIAGE System that is said to achieve quicker carriage returns.

The machine also has the DSCS Digital Stitch Control System, full-time spring-loaded sinker system, stitch presser, yarn gripper and cutter, takedown comb, and more.

SWG061N is the central model in a line-up of special Wholegarment knitting machines. With its compact size specially designed for producing a range of accessory items, SWG061N opens up a whole new genre of knit production, the company believes.

Gloves, socks, five-toe socks, hats, mufflers, leg warmers, neck-ties and other fashion accessories can all be produced in their entirety, with no sewing or linking required.

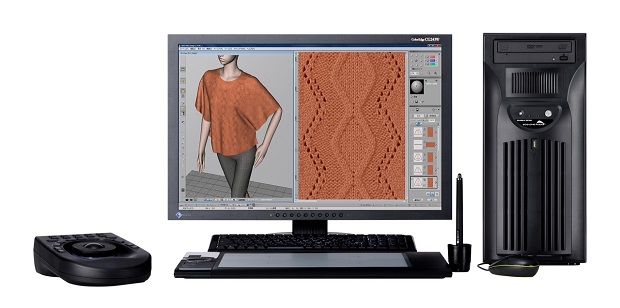

An ‘all-in-one’ 3D design system SDS-ONE APEX3 is at the core of Shima Seiki’s Total Knitting System and Total Fashion System concepts, allowing smooth workflow from planning, design and programming to production and even sales promotion.

APEX 3 also improves on the planning process through photo-realistic simulation capability, reducing time, material and cost from the sampling process with Virtual Sampling, Shima Seiki reports. Products can be checked with 3D simulation, such as 3D modelling, 3D fitting and 3D mapping.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more