New Digital Knits trend collection from Stoll

Leading flat knitting machine builder Stoll reports that it increased the number of three system machines it sold in the 2011 financial year. The German company said in a statement today that a clear trend can be seen in production towards the use of three efficient combined knitting systems as opposed to the conventional use of two systems. According to Stoll, application examples show that almost every pattern can be knitted in considerably shorter time using a thr

29th March 2012

Knitting Industry

|

Reutlingen

Leading flat knitting machine builder Stoll reports that it increased the number of three system machines it sold in the 2011 financial year. The German company said in a statement today that a clear trend can be seen in production towards the use of three efficient combined knitting systems as opposed to the conventional use of two systems.

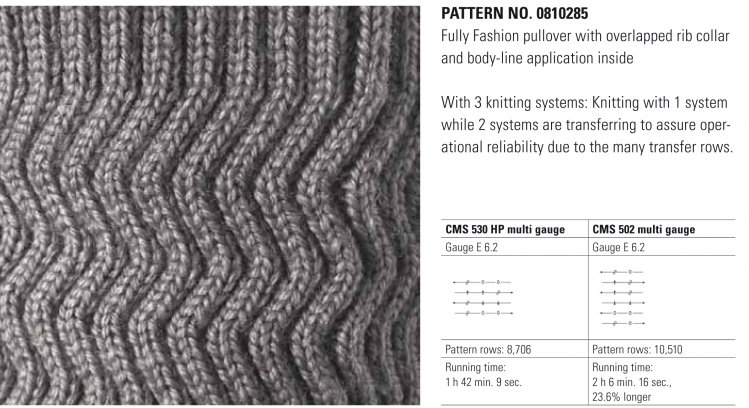

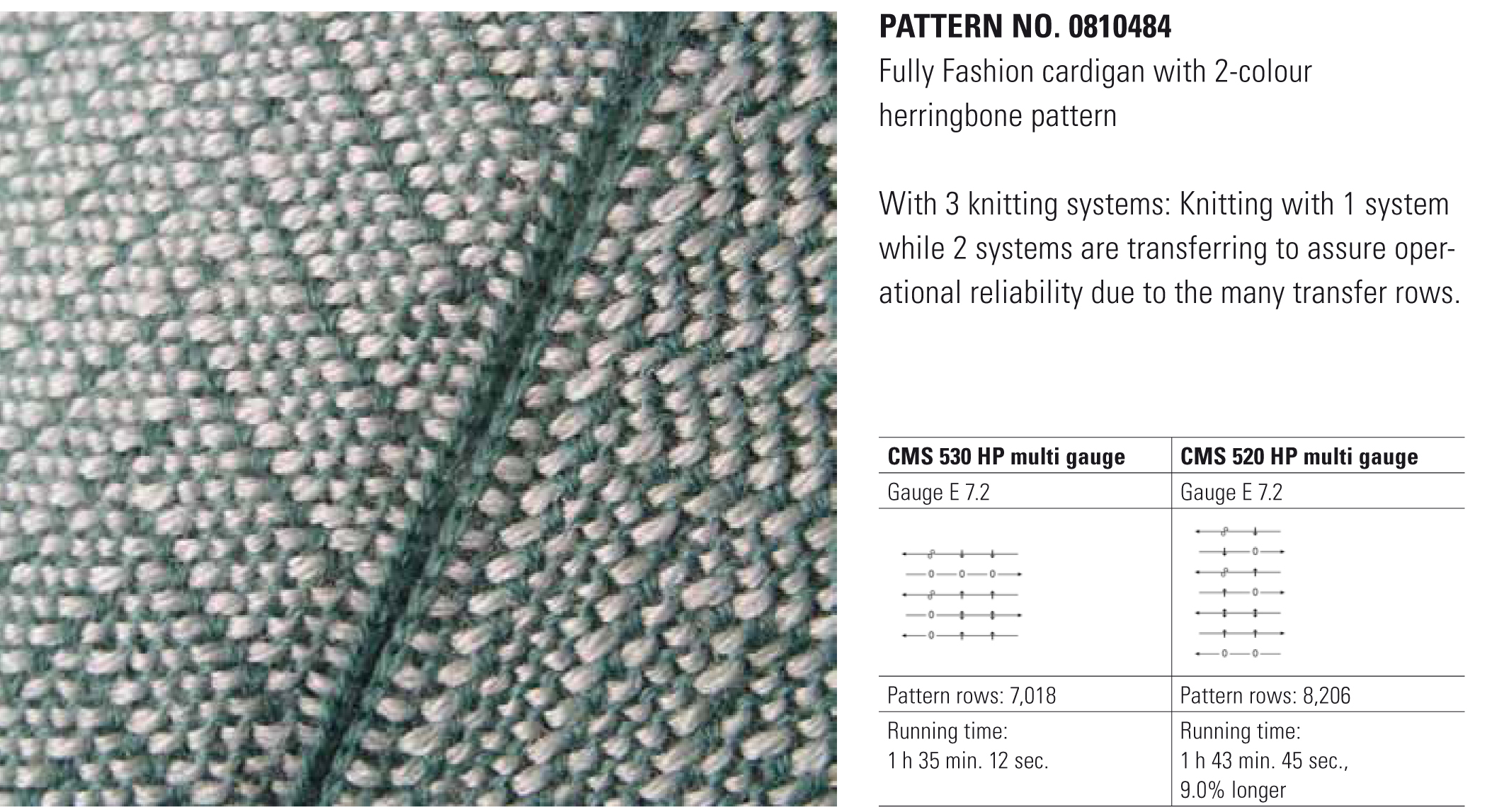

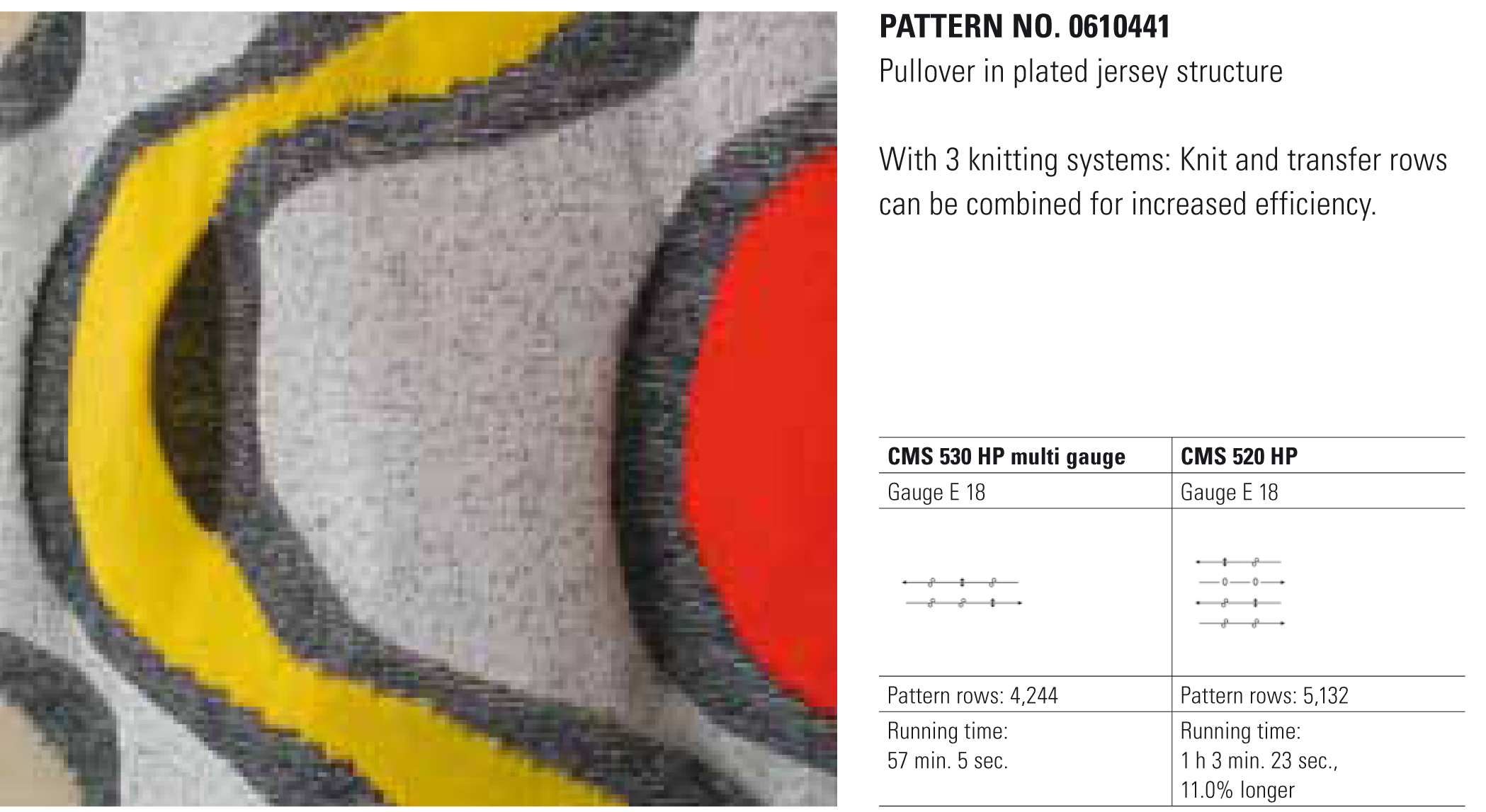

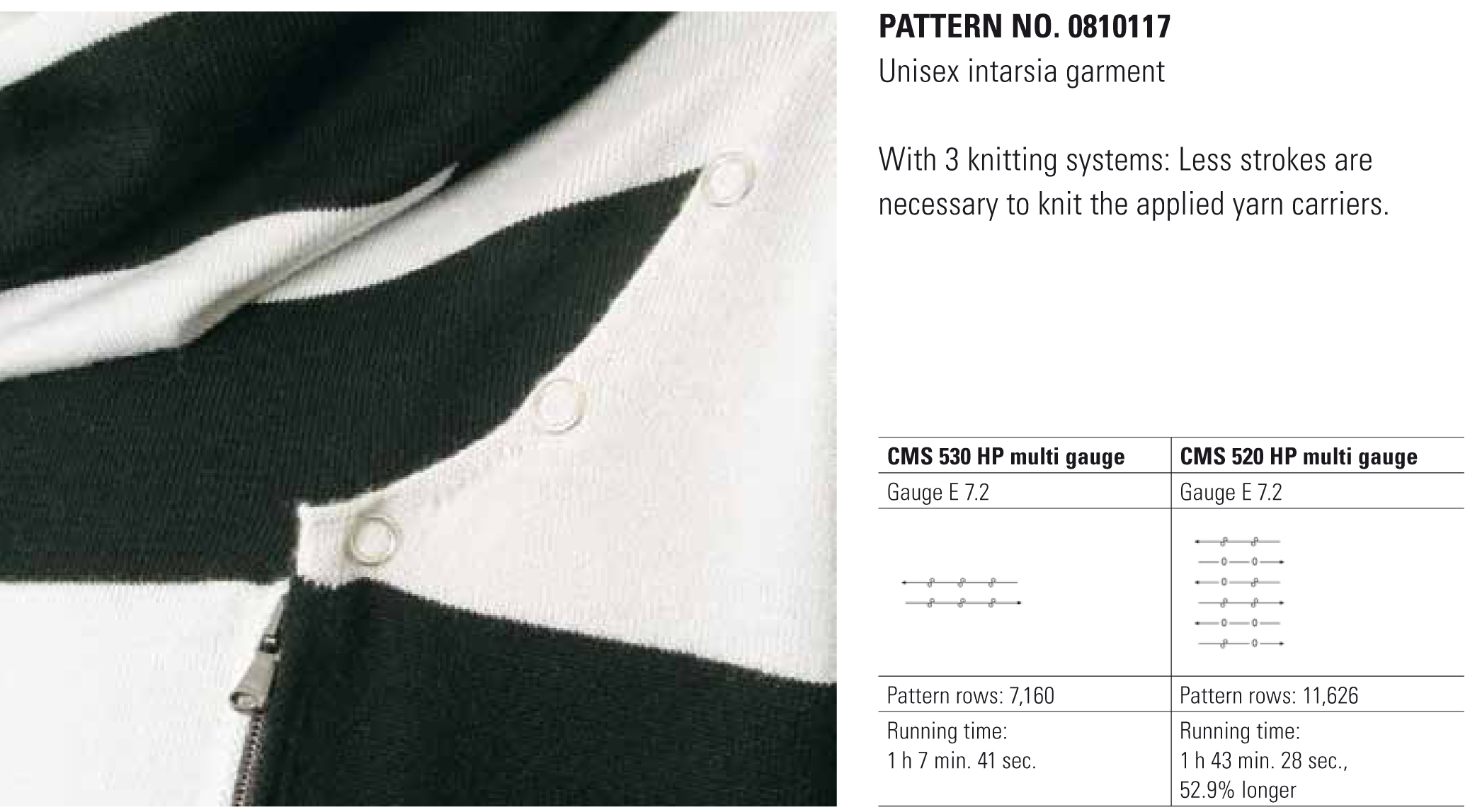

According to Stoll, application examples show that almost every pattern can be knitted in considerably shorter time using a three system machine. The company says that the additional system improves the machine utilization by reducing the number of machine strokes and shortens the knitting time by optimized pattern programs.

Stoll has offered its customers three system knitting in its latest HP (high performance) machine generation since 2009 and reports growing demand.

The innovative Reutlingen based company says it overcomes technical and run-time restrictions in the stitch formation and transfer process with 3-system knitting and offers his international customers the greatest level of freedom and flexibility in the production of knitwear for the world market.

"The fashion industry requires creativity and innovation. Stoll meets the challenges of the market. Even advanced fabrics with complicated processes can be knitted economically with three systems because the possible combinations of the three systems avoid empty rows and adapt the pattern programs to the greater variance," Stoll says.

"More knitting pieces can be produced through the shorter run-times. The three fully knitting and transferring systems compensate for the capital expenditure by the increase in productivity in short time. The increased productivity is achieved without increase of the energy consumption, without rise of the mechanical stress and without additional maintenance, care or lubrication overhead. The relative energy consumption per fabric piece gets lower," the company adds.

Stoll says that the expansion of the machine capacity with three systems begins to show with 2-colour and 3-colour jacquards with relief structures, with transfer intensive patterns, detailed accessories and many shapes. The more systems the better applies also to intarsia knitting and a three system carriage can work well with the large number of yarn carriers required in intarsia patterns.

Six strokes can be often reduced to two, Stoll says and its M1plus pattern software supports the customer in the development of extensive patterning by the systematic coordination of yarn carrier staggering.

In addition, when narrowing in fully fashioned knitting, Stoll says three systems are of great use in comparison with two systems. The following possibilities open up here - two systems knit while the third system is transfers or one system knits and two systems are used to transfer in 1 x 1, to guarantee a secure transfer, especially with tight fabrics.

Stoll is one of the leading manufacturers of flat knitting machines in the world and is based in Reutlingen in Germany. It was founded in 1873 and has approximately 1000 employees worldwide.

The company's flat knitting machines and pattern software which are used for the production of fashion knitwear, technical and medical textiles are exported to 70 countries worldwide.

With subsidiary companies, sales and service centres and representatives in many countries Stoll offers an integral service program. By innovative technical developments and with production concentrated in Germany, Stoll says it enables many knitting trends which are shown in its own inspiring fashion knitwear collections.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more