Stoll Knitting Training Centre unveiled in Shanghai

In this two part feature, we focus on an exciting new development affecting the UK’s knitwear design, manufacturing and retail sectors – the opening of a new knitwear Design Centre in the country’s knitwear capital Leicester, backed by leading flat knitting machine builder H. Stoll GmbH & Co KG of Germany.

2nd July 2013

Knitting Industry

|

Leicester

In this two part feature, we focus on an exciting new development affecting the UK’s knitwear design, manufacturing and retail sectors – the opening of a new knitwear Design Centre in the country’s knitwear capital Leicester, backed by leading flat knitting machine builder H. Stoll GmbH & Co KG of Germany.

Stoll GB Ltd, the sole agent for Stoll flat knitting machines in the UK, officially opened its new Leicester based knitwear Design Centre on the 10th May 2013. The new facility, which is based in Leicester city centre on Craven Street at the heart of the East Midlands knitwear industry, offers knitwear development facilities and training for manufacturers, designers and retailers, as well as technological solutions.

The centre has the full backing and support of Stoll (H. Stoll GmbH & Co.KG) the leading German manufacturer, which has been building knitting machines for over one hundred and forty years, and is equipped with the latest generation Stoll flat knitting machines.

Around 40 knitwear manufacturers are thought to be still operating in Leicester, which is globally renowned for its knitwear manufacturing and once mighty knitting machine building industry.

David Williams, owner and Managing Director of Stoll GB, who has many years of experience in supplying machinery and services to the knitwear industry globally, aims to offer services which currently do not exist.

“There is a need for a knitwear development facility in the UK which ties designers and retailers, who are predominately London based, with the manufacturing base here in Leicester and the surrounding area,” Williams explains.

“We have spent the last year or so working with designers and retailers developing their products and making available knitting machinery, technicians, yarn resources and making up equipment. We have managed their expectations carefully and are now ready to open the doors of our new Design Centre to a wider audience.”

During its pilot phase the Design Centre has worked with a wide range of designers and retailers and amongst the up and coming knitwear designers there have been a number of success stories. Designers are full of praise for the initiative, especially those who are faced with the dilemma of where to go to get their early collections developed. Two London based designers have already purchased their own Stoll machines after successfully working with the Design Centre to develop their collections.

Knitwear designer Alice Palmer who has her own label (www.alicepalmer.co.uk ), uses Stoll GB’s Design Centre regularly. UK trained Alice, whose edgy knitted dresses sell in the Middle East, Hong Kong and Italy works with the centre’s technicians to develop shaped knitted pieces which she puts together using the in-house make up and finishing equipment.

More established brands and retailers use Stoll GB’s Design Centre to develop prototype garments which are subsequently refined and put into production by experienced manufacturers in the UK or elsewhere in Europe.

London based designer Anna Wheeler, sometimes uses two or three machines at a time at the centre when she is putting together a collection for her company’s high-end brand. Sample garments and knit programs are sent to the company’s knitwear manufacturer in Italy where they are made ‘production ready’ and subsequently manufactured.

“Being able to work alongside the technicians at Stoll GB’s Design Centre has enabled me to develop my creativity in a truly original way, which for me as a designer is very important,” says Anna.

“I have been able to work on a one to one basis with the fully trained and experienced technicians. This has allowed me to oversee every step of my fabric development, which is very exciting.

All of the technicians at the Design Centre have a vast knowledge and understanding of stitches and techniques and it has been invaluable discussing and exploring my design ideas together with them. They have also helped me to evolve my designs to be more commercially viable and production friendly, without losing my creativity.”

Stoll GB currently has three experienced technicians programming for clients, together with a trainee programmer, a Nottingham Trent University (NTU) fashion knitwear design graduate. The company is also planning to take on two more graduate designers this year and is recruiting another experienced Stoll technician.

Austrian born NTU graduate Maria Zwerger is currently on a one year program at Stoll GB where she is learning to program the latest generation Stoll CMS machines. Maria, who has previously had spells at the Stoll Fashion & Technology Centers in New York and Germany, says she aims to be “a hands on designer – a designer that stays close to the process. And therefore learning to program Stoll machines is a must.

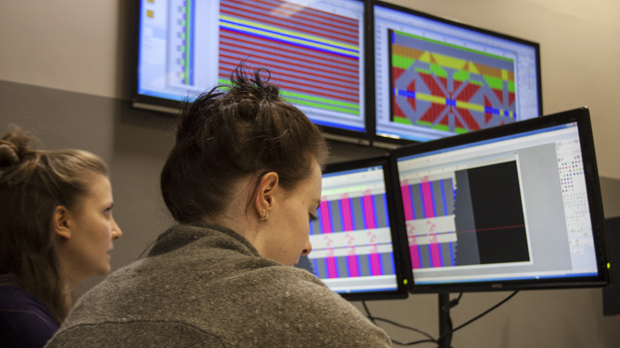

Stoll GB’s Design Centre is a combined knitwear design studio and machine showroom - floor to ceiling glass doors separate the two. The design studio is equipped with the latest Stoll M1 design and programming systems and the showroom houses a range of the latest generation Stoll CMS models in a range of gauges, which are:

Stoll GB has also been running knitwear training courses for major retailers where retailers can learn the basics of knitting technology and knitwear sample development. Training courses already held involve learning basic knit structures and fabrics analysis, together with garment assembly.

Managing Director David Williams comments: “The Design Centre is a unique concept within the UK, where designers can work alongside technicians to develop and realise their design ideas. We’re also conveniently located in the centre of the country with good rail and motorway links, at the heart of the manufacturing base.”

“Knitwear designers and product developers can access highly qualified and industry experienced technicians. Usually we recommend that the designer or developer works on site at the Design Centre with our technicians so that they can be on hand to input into and oversee the complete sampling process.”

“Traditionally, a designer would give instructions to a technician and return to approve the first sample after it has been programmed and knitted. This back and forward process would continue until a final sample was produced. We find that a more ‘multi-disciplinary’ approach works better, where technician and designer work more closely together.”

“We look forward to welcoming the UK’s knitwear designers, manufacturers and retailers to our new Design Centre,” David Williams concludes.

Click here to contact the Stoll GB Knitwear Design Centre

Coming soon: Part 2 - Stoll Backs UK Knitwear Design Centre

View more great Design Centre images and 'LIKE' Knitting Industry on Facebook.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more