Groz-Beckert welcomes 4,000 visitors at ITMA Asia

Global leader in the manufacture of knitting needles and elements Groz-Beckert, impressed at ITMA Asia with a real show of strength. The Albstadt based company exhibited its latest innovations in knitting, weaving and nonwovens at very impressive stand situated in the main knitting hall. Groz-Beckert brought a slightly smaller version of the stand it had built for ITMA in Munich last year from Germany together with its design and construction partner. The stand was

2nd August 2008

Knitting Industry

|

Shanghai

Global leader in the manufacture of knitting needles and elements Groz-Beckert, impressed at ITMA Asia with a real show of strength. The Albstadt based company exhibited its latest innovations in knitting, weaving and nonwovens at very impressive stand situated in the main knitting hall.

Groz-Beckert brought a slightly smaller version of the stand it had built for ITMA in Munich last year from Germany together with its design and construction partner. The stand was so impressive that other leading machine builders were keen to know who had designed it.

Mrs Edelgard Keinath, Groz Beckert PR & Advertising told KnittingIndustry.com: “As a market leader we feel it is important to maximize the opportunities available to us, especially at major exhibitions such as ITMA Asia. We also think it is very important to do things to an excellent standard and that is why we have taken great care over the design and construction of our booth.”

Groz-Beckert, a world leader in high-technology parts and tools for the production of textiles is keen to be seen as developing from a supplier to an innovation, process and service partner offering innovative systems and service packages. It develops solutions in cooperation with machine builders and textile producers for a mutual success.

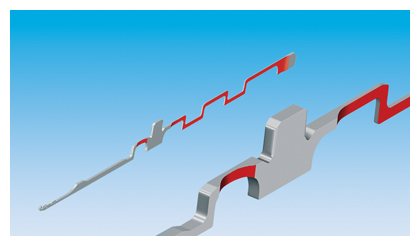

Litespeed needle

Litespeed needleLitespeed is Groz-Beckert’s latest generation of needles for high-performance circular knitting machines. The main difference in construction compared to the previous generation needle is Litespeed’s tapered shank which reduces the lateral friction between needle and trick wall. The tapered section allows the lubricant to flow in easily so that the needle acts like an oil pump distributing the lubricant between needle shank and trick wall, guaranteeing the optimum film of oil.

In addition to easing friction Litespeed also helps reduce wear and lower temperatures and energy consumption. According to Groz-Beckert Litespeed needles facilitate cold machine start and reduce machine noise. The company’s Litespeed project also includes the analysis of needle oils and it now offers producer-independent oil advice, trainings and Needle Oil Test Kits for oil analysis.

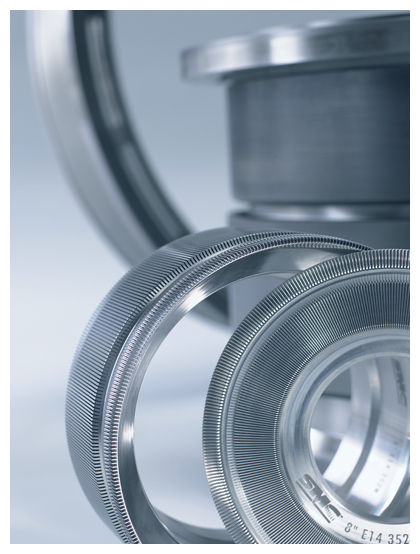

SMC precision cylinders

SMC precision cylindersGroz-Beckert’s SMC now offers the world’s finest 66 gauge cylinders for fabrics with up to 2600 loops per square centimetre, the individual loops being almost invisible to the naked eye. Based on its unique product range from gauges 3 to 66 in almost all diameters up to 60 inches, SMC showed a 28 gauge, 34 inch knitting cylinder for single jersey machines and a 44 gauge, 34 inch cylinder to satisfy the growing demand for ultra-fine gauge fabrics.

Customers benefit from the synergy of the cooperation between SMC and Groz-Beckert. The combination of SMC cylinders and Groz-Beckert knitting machine needles and system parts, all meeting highest demands on precision and uniformity, guarantees high productivity and process security for the production of innovative, fine, high-quality fabrics used for high-class fashion. With such fabrics/clothing, the customers can achieve higher prices and increase their margins significantly.

Also on show in Shanghai was Groz-Beckert’s complete knitting head which it now offers to circular knitting machine builders fitted with elements, and its Optiloop coating system. Optiloop offers wear protection for the yarn-gliding area of loop-forming elements, including needle hook and latch, especially when highly twisted, abrasive polyester, acetate and viscose yarns or yarns based on copper, steel, silver wire, glass fibre and carbon fibre are processed.

Simple ideas are often very practical and Groz-Beckert’s innovative packaging for handling of sinkers is a good example. An open patented cut-out on the upper butt edge of the sinker facilitates easy handling. The cut-out is filled with an elastic retainer to allow individual packaging and removal and reduce preparing time as the sinkers are already aligned.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more