-300x192-cropped.jpg)

New shoe fabric patterns with COP 5 M-EL

Karl Mayer has launched a new Pattern Editor which allows users of its RS2 EL-F and RS3 EL-F raschel net producing machines to quickly develop new patterns. Until now, developing new net products on Karl Mayer’s RS2 EL-F and RS 3 EL-F raschel machines meant a lot of trial and error and the development was carried out with the assistance of the machine builder. The customer came up with a new lapping movement and sent the notation to Karl Mayer in Obertshausen who

14th July 2008

Knitting Industry

|

Obertshausen

Karl Mayer has launched a new Pattern Editor which allows users of its RS2 EL-F and RS3 EL-F raschel net producing machines to quickly develop new patterns.

Until now, developing new net products on Karl Mayer’s RS2 EL-F and RS 3 EL-F raschel machines meant a lot of trial and error and the development was carried out with the assistance of the machine builder. The customer came up with a new lapping movement and sent the notation to Karl Mayer in Obertshausen whose technicians produced a metal pattern disc before returning to the net producer. Often modifications had to be made and the whole process would be repeated which could be both very time consuming and expensive.

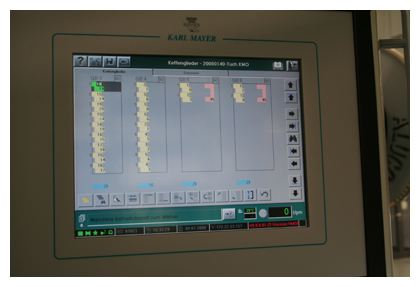

Karl Mayer has now shortened the process considerably by introducing a special Pattern Editor which allows net producers to process new net constructions directly on their raschel machines, shortening the overall time it takes to produce a pattern disc for a production run. According to Karl Mayer, the new Pattern Editor which is integrated into the Kamcos system allows easy input of the lapping movement for producing sample fabrics. When the desired sample has been finalized, Karl Mayer then produces the optimum electronic pattern discs for the production run.

Karl Mayer has now shortened the process considerably by introducing a special Pattern Editor which allows net producers to process new net constructions directly on their raschel machines, shortening the overall time it takes to produce a pattern disc for a production run. According to Karl Mayer, the new Pattern Editor which is integrated into the Kamcos system allows easy input of the lapping movement for producing sample fabrics. When the desired sample has been finalized, Karl Mayer then produces the optimum electronic pattern discs for the production run.

The data carriers contain the pattern for all the guide bars and the associated lapping arrangement. Production information, such as the number of stitches, yarn feed values and product data, can be input at the Operator Interface and stored using the Pattern Editor. The result is a simple system for managing the pattern data and high speed mass production can start as soon as the electronic pattern disc has been loaded into the machine.

Karl Mayer claims that the extra flexibility that this system gives when developing products, together with the shorter development times, enables manufacturers to access new markets and open up new applications

5740 mm = 226 inches

E6/6 = 1 Needle per 25,4 mm

Single needle bar, tongue bar and knock-over comb bar, 2 ground guide bars, GB1 stitch-forming

Motion Control / Single Speed for the control of the basic functionsPrinter interface / 3 ½" floppy disc drive for reading and writing Operator Interface / 12,1" Color Touchscreen for the production display,Network interface (Ethernet) for networking and connection for the relevant data acquisition and Teleservice Integrated yarn inspection Laserstop for yarn let-off devices and ground guide bars

FTL1 (film cutting and stretching aggregate)Final tape max-width: pillar stitch 2 mm / weft 1 mmFilm heating, continuously adjustable regulation of the stretching ratio, 2 three-roller feeding devices with idler roller device for readjustment, controlled via Motion Control

Electronically controlled, 4-roller system driven by geared motor, controlled via Motion Control

No. 39With friction drive, driven by geared motor, speed-regulated via Motion Controltraversing device, pneumatic pressure-roller device and pneumatic loading device for a prepared fabric beam, 2 fabric beamsmax. batch diameter of 300 mm (12 inches)

electronic guide bar drive (EL),GB1: 1-0/0-1/0-1/1-0//GB2: 0-0/1-1/2-2/1-1//

Speed-regulated main drive, power-failure safe, incl. precise-positioning function, totale connected load 38 kVA

Rights for technical modifications reserved!

Technical data: courtesy of Karl Mayer Textilmaschinenfabrik GmbH

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more