Mayer & Cie. rewarded at CAITME

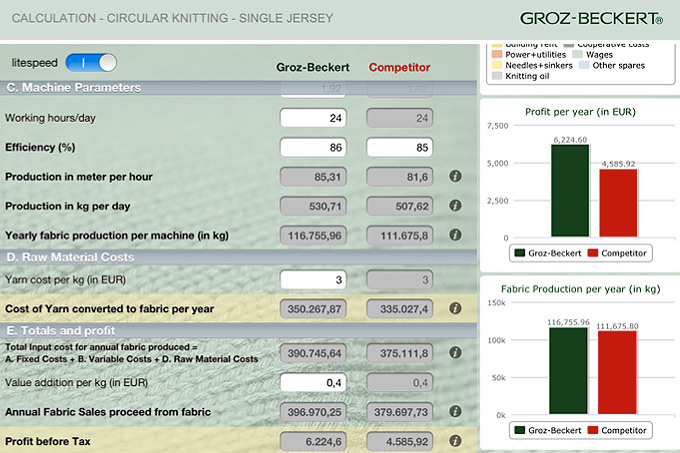

In a recent issue of its company newsletter Groz-Beckert presented its Productivity Benchmark, the Groz-Beckert efficiency calculator that shows in a playful way how even small changes in individual factors have a big impact on productivity. The German company has now published details of the second instalment of the success story, which is about supporting its customers in increasing productivity in the form of jointly conducted field trials. The results are impressive.

8th April 2014

Knitting Industry

|

Albstadt

In a recent issue of its company newsletter Groz-Beckert presented its Productivity Benchmark, the Groz-Beckert efficiency calculator that shows in a playful way how even small changes in individual factors have a big impact on productivity. The German company has now published details of the second instalment of the success story, which is about supporting its customers in increasing productivity in the form of jointly conducted field trials. The results are impressive.

To demonstrate the added value for customers that small but targeted adjustments can bring, Groz-Beckert started to carry out field trials in different markets that demonstrate how small changes in individual factors can have a specific impact on its customers' production, which it backs up with facts and figures.

“To produce as broad a spectrum of results as possible, these field trials were carried out on the premises of very different customers and at different-sized companies – from commission knitters all the way to multilevel operations,” the company says.

Each of the field trials began after regular and proper maintenance of the machine, i.e. after removal of the yarn guide head, the cams, and the needles and system parts. After cleaning of the cylinder and lubrication, the machines were reassembled.

For an increase in output, it's not only the needle that has to fulfil the very highest quality standards, Groz beckert explains: “The prerequisite for reliable results in a field trial is of course also precise adjustment of the machine as well as its impeccable condition. This includes checking and adjusting of the horizontal and vertical concentricity of the cylinder, setting of the yarn guides, and replacement of damaged cam parts.”

Only in this way can the machine produce high-quality merchandise while making optimal use of the efficiency of Groz-Beckert products, the company reports.

Based on an analysis of knitted fabrics previously produced on the machine, and of used needles and sinkers, the necessary optimizations were defined ahead of the trial. In one case, for instance, a specific needle type from the Groz-Beckert range, ideally suited to the customer-specific application, was selected. Once these conditions were established, the tests began, with a gradual increase in machine speed by up to five revolutions per minute.

All customers who participated in the field tests are said to have been initially sceptical. Although the machines are designed for high speeds, and the Groz-Beckert needle is said to represent superior performance and quality, machines are frequently operated at lower speeds.

But the results of the field tests were convincing, Groz-Beckert states: “During the period from August to November 2013, at trials carried out in the Brazilian market, all customers consistently confirmed an improvement in performance.”

Since the customers had initially been rather reserved about the tests, Groz-Beckert says it began by only recommending an increase in machine speed by two revolutions per minute.

Three customers, encouraged by the initial success at a higher rotational speed, dared to increase the machine speed even further. One of them increased its machine speed by as much as five revolutions per minute without any negative results, Groz-Beckert reports.

“The respective clients' machine speed increases thus lay between two and five revolutions per minute. Accordingly, productivity rose from 6.7% to 18.2%,” the company states.

After taking part in the field tests, Malhas JN a company which is part of the Brandili Group, a children's fashion manufacturer, thanked Groz-Beckert for being given the chance to participate and congratulated the company on its project.

Three months with an increase in machine speed of five revolutions per minute resulted in a productivity increase of around 17% for the Brandili Group company, with no negative effects detected, where either quality or maintenance were concerned. Malhas JN summed it all up with the words: "In addition to increased productivity, we have also gained expertise and confidence. Thank you, Groz-Beckert!"

Groz-Beckert thanked all of the other companies that took part in the field tests for and their trust and the pleasant cooperation. The Groz-Beckert agency NS Importação e Comércio Ltda. was also thanked for the optimal preparation of the project and the monitoring of field tests on-site.

The results of the field trial will soon be published in a brochure containing detailed data on the field tests that were performed. Further details can be obtained directly from Groz-Beckert.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more