Retailers toughening up on taking back

Paid content

Pailung high-speed knitting machines shine at ITMA 2023.

20th June 2023

Knitting Industry

|

Milan

At the recent ITMA 2023 in Milan, leading circular knitting machine manufacturer Pailung exhibited its latest high-speed machines, which deliver more production capacity with less energy consumption, effectively boosting textile manufacturers’ productivity while lowering their costs.

Textile manufacturers have to improve their efficiency. They are under constant pressure to produce more, faster, and for less cost. Although that might seem difficult, it is now possible thanks to new innovations in high-speed circular knitting machinery.

Lately, Pailung has been collaborating with its customers to build faster and more efficient knitting machines. After months of discussion, which led to a number of major improvements, it has just finished testing the new machines and the results are in.

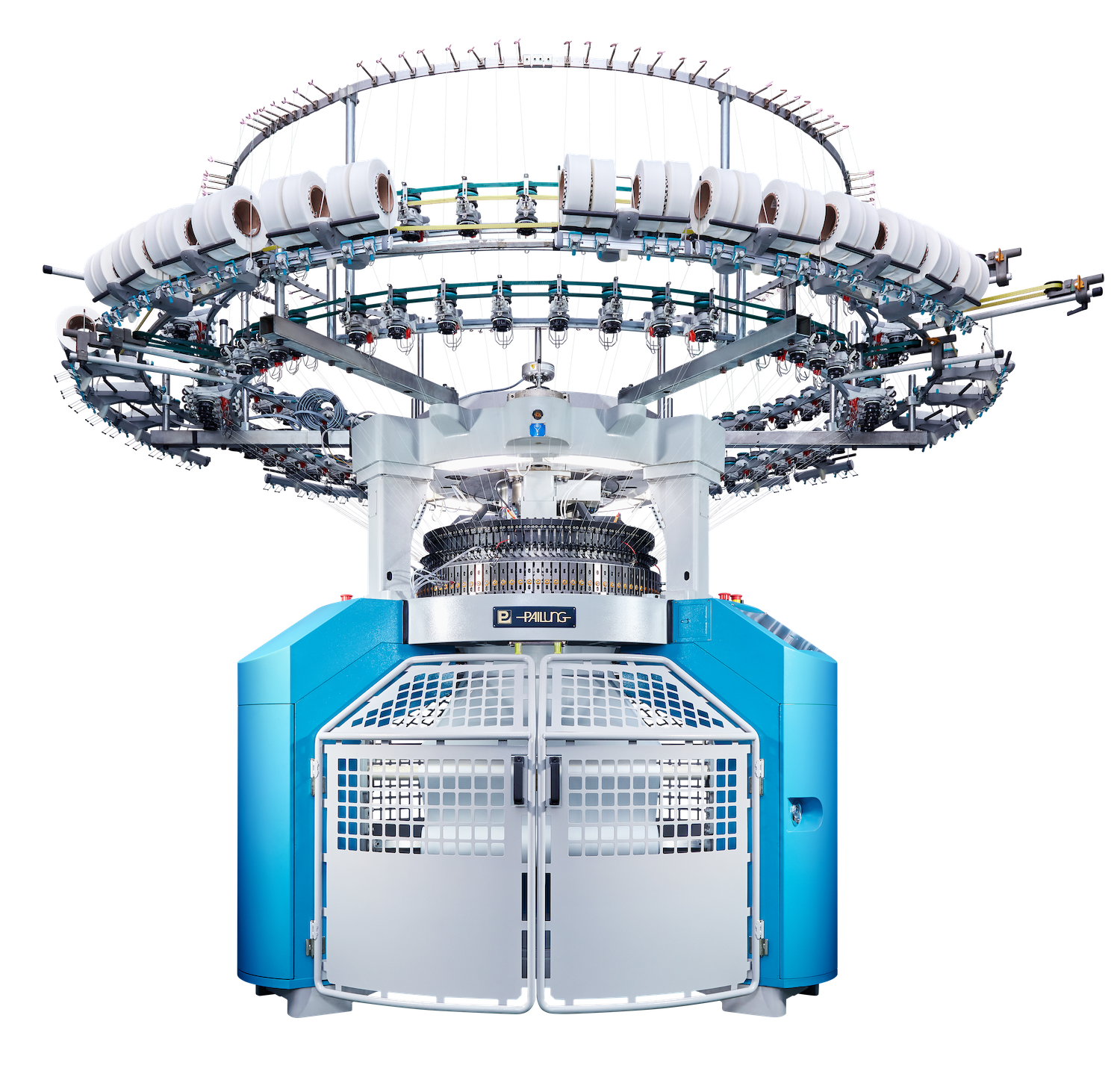

From June 8-14, Pailung exhibited four new high-speed circular knitting machines (from the Knitel series) at ITMA 2023, the world’s largest textile and garment technology exhibition in Milan.

Pailung’s optimized high-speed knitting machines

KS3B PLUS HS

The KS3B PLUS HS is a circular knitting machine capable of producing six popular fabric types:

- Plain Single Jersey

- Plain Single Jersey + Lycra

- Pique

- Pique + Lycra

- 2 Yarns Fleece

- 2 Yarns Fleece + Lycra

Compared to its predecessor, the KS3B, this machine offers even higher speeds, and lower energy consumption at top speed. Operating at 45 rpm, this machine consumes less energy than the KS3B consumes at 32 rpm and produces up to 40% more fabric in one day.

KS3B PLUS HS stands for high speed. Whereas the KS3B could only reach a max speed factor of 960, the KS3B PLUS HS reaches a max of 1350. It is capable of producing the same six popular fabrics as KS3B, but 25-40% quicker, resulting in a massive capacity increase. To boost versatility, the machine can be modified using a conversion kit to further produce Terry and 3-End Fleece fabrics.

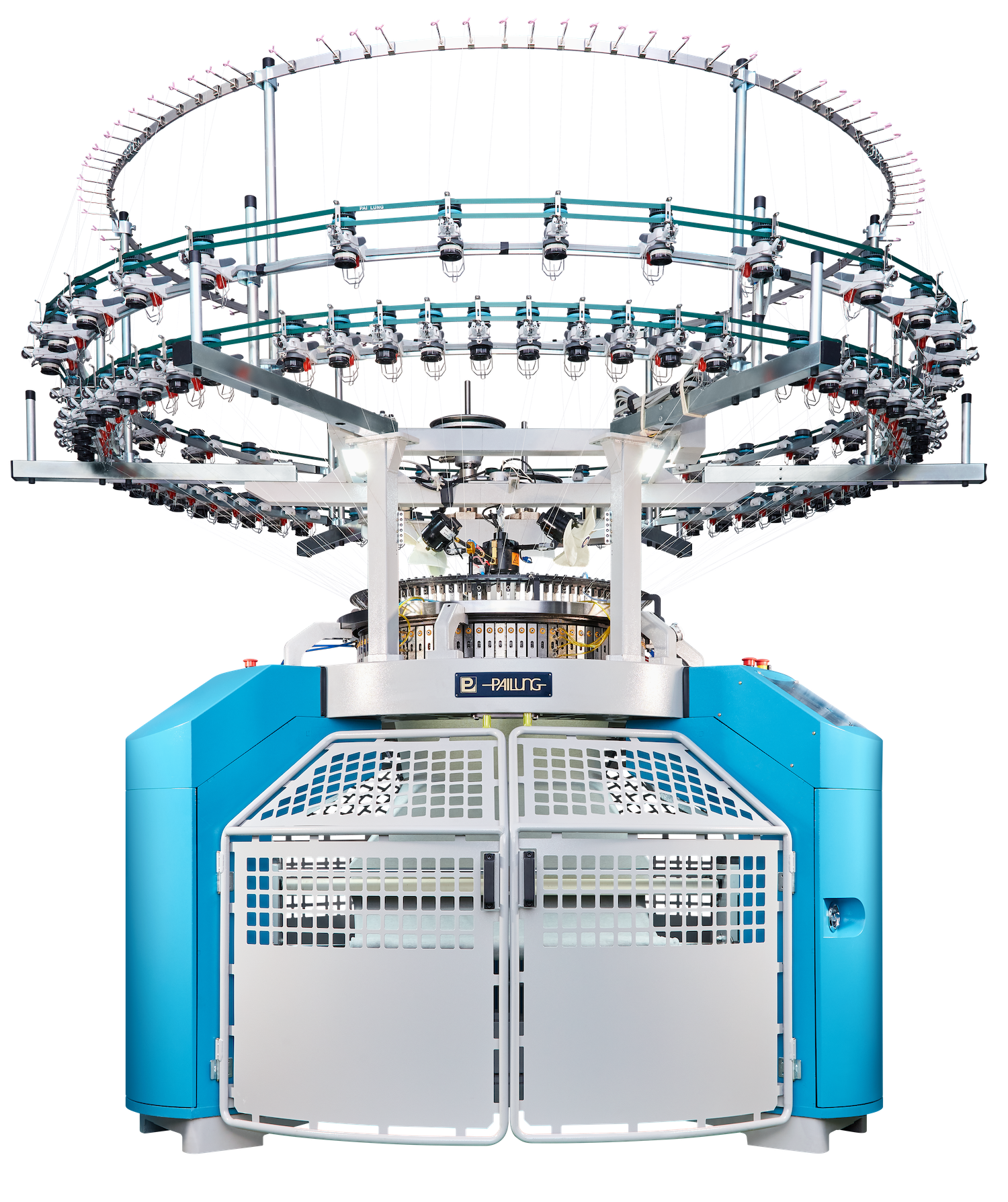

KD3.2B PLUS

The KD3.2B PLUS model produces the following six popular fabrics:

- Interlock

- 8 Lock

- 4-Way Stretch

- Scuba- Swiss Fleece

- Spacer

This high-speed Interlock circular knitting machine specs a 2+4 track, 26”-42” cylinder, and a 22–32-gauge setup. It produces the above-mentioned six fabrics at higher capacity compared to its predecessor, the KD3.2B. For example, when knitting Interlock, 8 Lock, and 4-Way Stretch fabrics, the 28G KD3.2B PLUS has a capacity increase of around 25-33%.

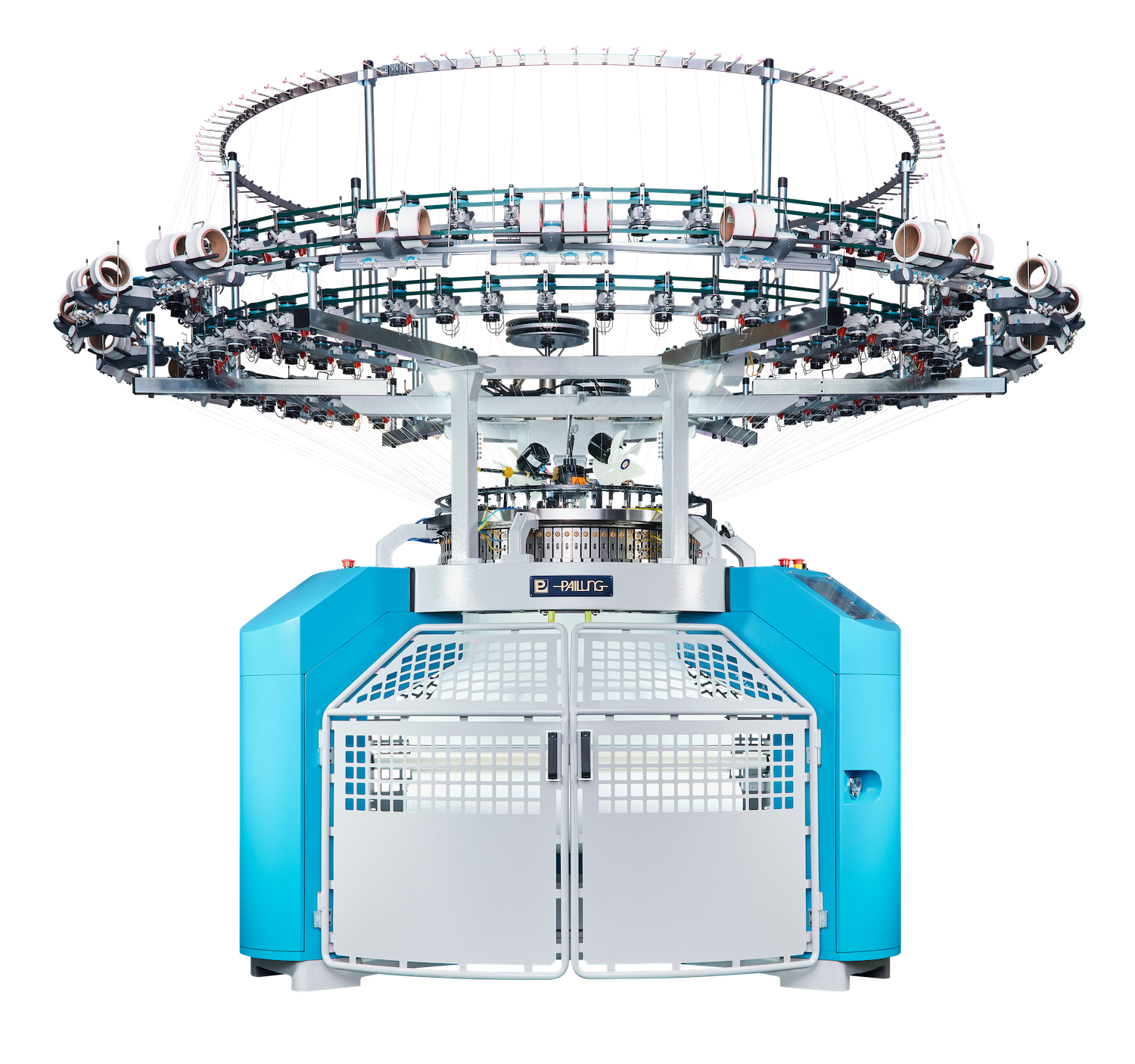

KF3B PLUS

This machine produces 3-End Fleece and specs a 13”-40” cylinder, 14–28-gauge setup. It produces 3-End Fleece at an average 19% capacity increase compared to its predecessor. For example, when producing 20G 3-End Fleece, the capacity increases by 25%.

KSP PLUS

This machine is a high-speed Terry (ordinary plating) circular knitting machine that creates fabric with a pile height of 1.2mm-2.8mm. It has improved greatly, with 25% capacity increase at 20G, and 30% capacity increase at 28G, compared to its predecessor.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more