Good year for EU circular and socks knitting machine producers

The leading machine builder will unveil its brand-new large diameter INNOTAS machine at India ITME 2022.

8th December 2022

Knitting Industry

|

Brescia, Italy

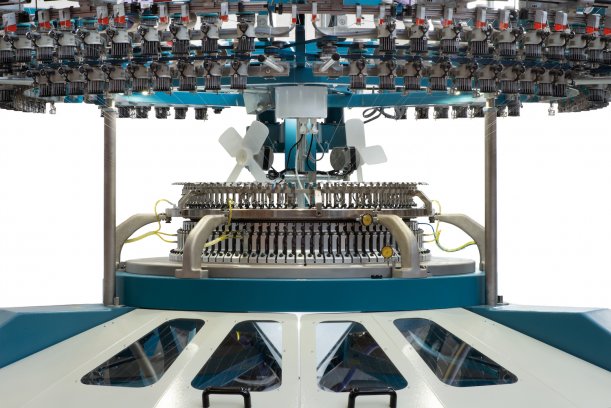

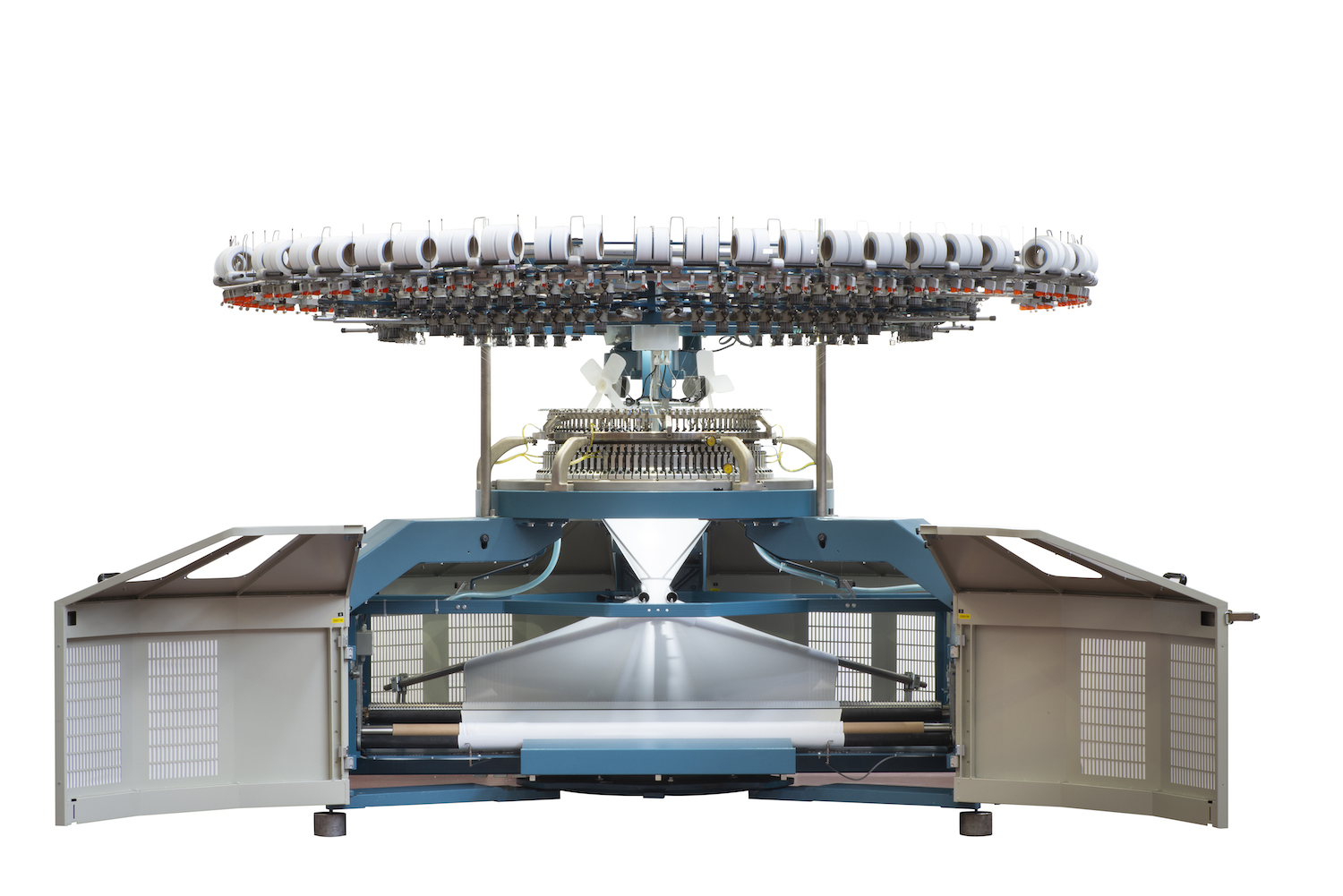

Leading Italian circular knitting machine builder Santoni is launching a brand-new large diameter machine called INNOTAS at the upcoming India ITME show in Noida, India (Hall 15 - Booth D20).

Santoni will be enhancing its presence at the show, by highlighting its constant technical research through its wide range of samples made by its circular knitting machines, giving manufacturers the opportunity to explore all the innovative production processes patented by Santoni.

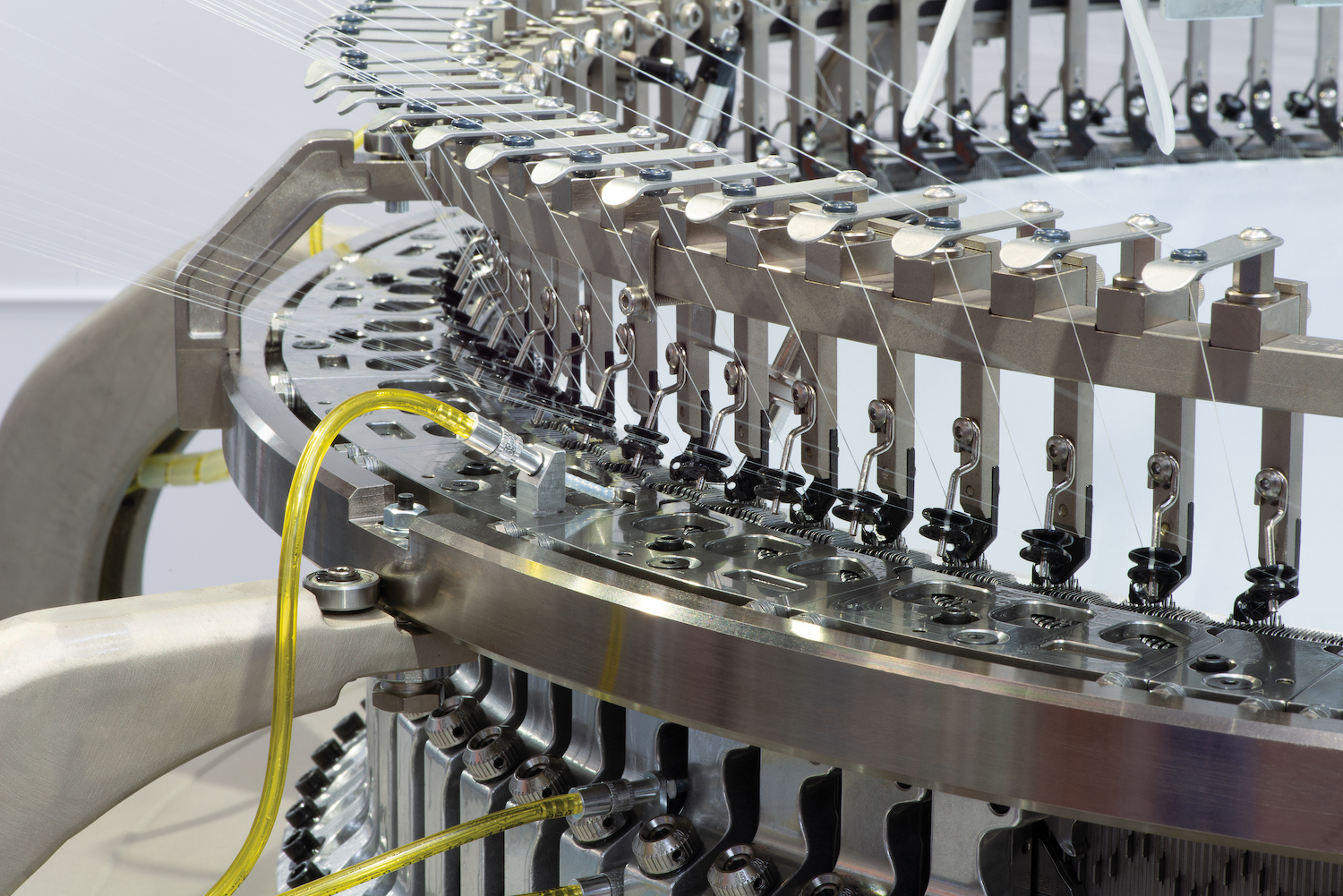

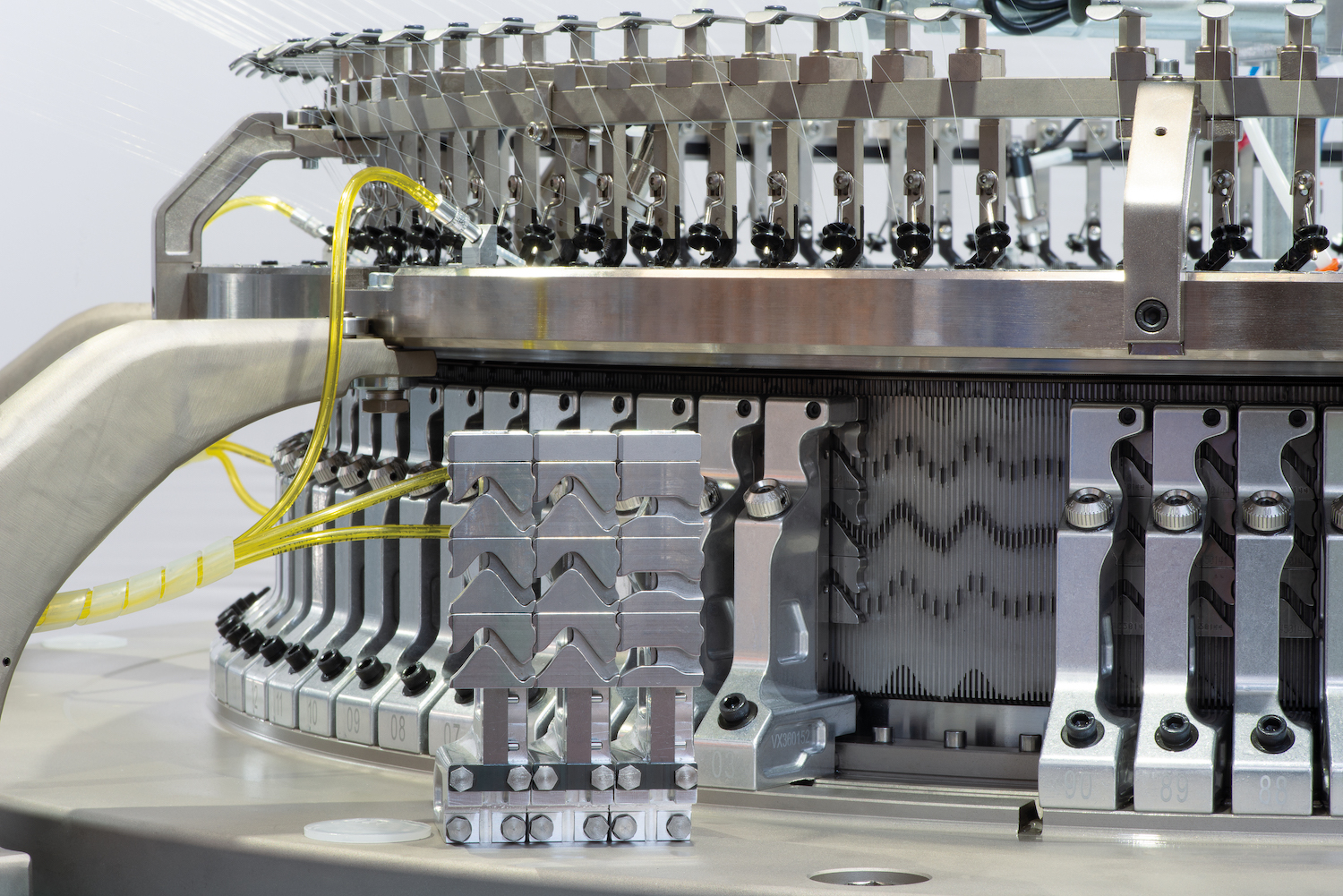

“The latest entry among Santoni large diameter machines is INNOTAS, a single jersey machine with 3 feeders per inch, capable of knitting up to 4 track structures, which has been designed to manage lint,” says Santoni Marketing Manager Patrick Silva.

“Thanks to a patented self-cleaning system, in the complete absence of external devices, the machine eliminates from the knitting head the accumulation of fibres, fluff and lint, typical of knitting productions. The machine doesn't require scheduled maintenances, thus saving time and avoiding the complications that arise from such operation.”

“Reducing machines downtime means being more productive and preserving sinkers and needles life because the absence of fluff/lint leads to an increase in performance and a reduced wear rate,” Mr. Silva adds.

“Moreover, thanks to low shank needles, oil consumption is reduced by 50%. This also means absence of oil lines on fabrics, thus resulting in a high quality. INNOTAS achieves energy savings of 15% compared to a standard machine where the increase of power consumption is directly related to the quantity of fluff/lint accumulated,” says Silva.

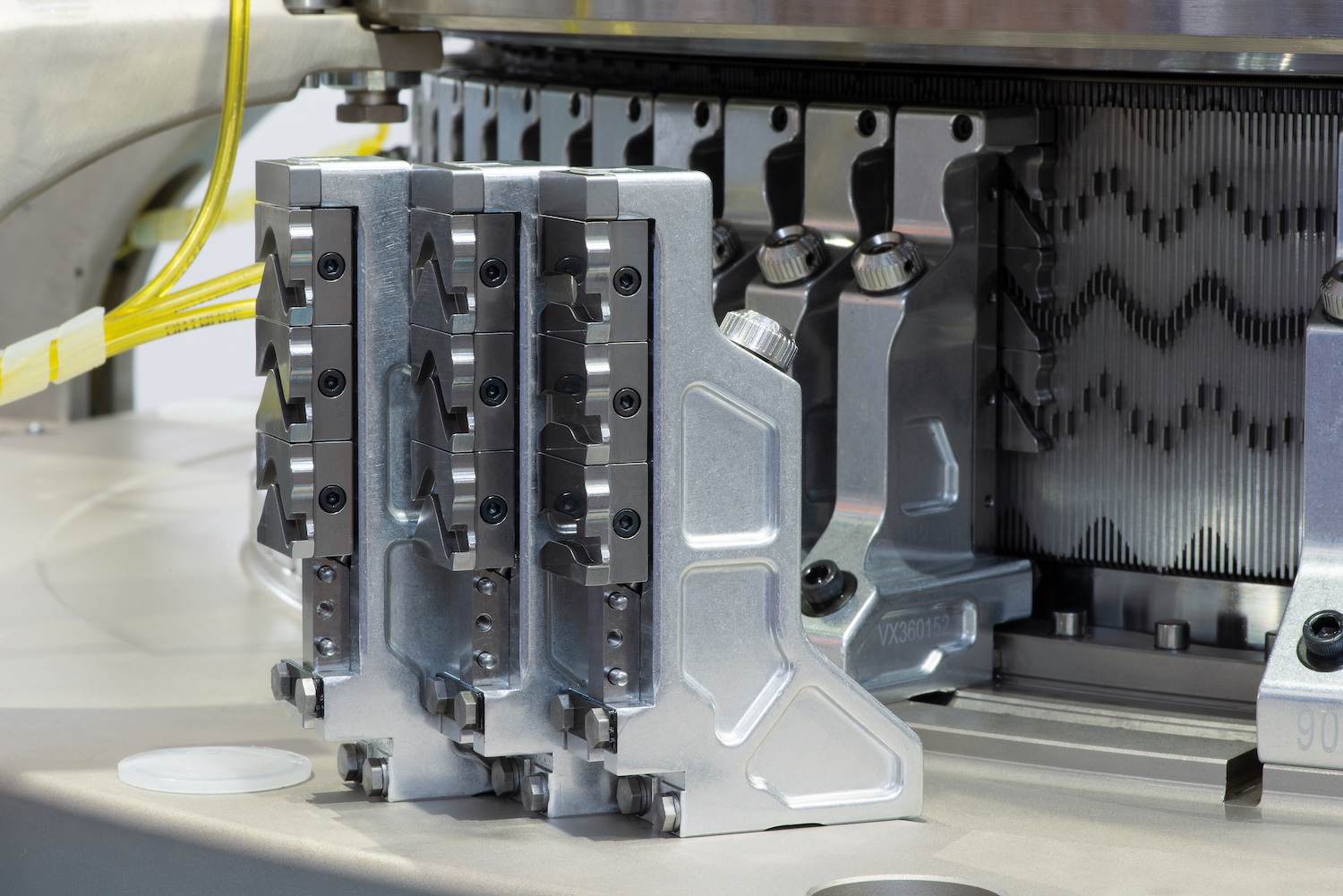

Other large diameter Santoni machines which are worth mentioning are ZENIT OPEN and ZENIT-F2. Both are single jersey machines to produce four cam track stitch structures. The Zenit is a very versatile machine having 3 feeders per inch and is available with tubular as well as with Open Width Frame. Camboxes are very light and are made from a special aluminium alloy named Ergal, giving exceptional heat dissipation properties. Ergal helps avoid dimensional changes due to the variation of temperature between the starting and the regular running of the machine. The yarn carrier head is made of Black Zirchonium, which allows better visibility of the elastomer.

At ITME 2022 manufacturers can also see first-hand seamless samples. Amongst Santoni’s seamless knitting machines is the renowned model SM8-TOP2V, one of the company’s best sellers, together with the SM8-TR1S and the SM8-TOP4J, which have been completely updated and equipped with new structural elements and electronics.

Going into detail, the SM8-TOP4J is a single jersey electronic circular machine with 8 feeds, from 12” to 22”, with four points of selection needle by needle on each feed. According to Santoni, it is perfect for producing single seamless garments for many textile sectors giving the possibility to create different stitch structures and to position more colours on the same course, compared to the standard models. Terry possibility is available on request.

On the other hand, the SM8-TR1S is a single jersey electronic circular machine with 8 feeds, from 12” to 22”, with two selection points on three technical ways for the knitting feeder plus 1 selection point to produce fishnet or ladder proof stitch structures (Santoni patent).

In shoes, Santoni is promoting its innovative single-cylinder XT-MACHINE, which uses a revolutionary 3D intarsia technology that maps the foot for perfect fit and form, offering unlimited patterns and colour combinations as well. This machine can produce, in record time, lightweight uppers with breathable mesh areas and eyelets, that are ready for the application of the sole, the company adds. The XT-MACHINE can knit in sculptured terry cushioning and transfer-stitch points on the same course, becoming the first machine in the world able to do that.

When it comes to sock knitting machines, it’s worth mentioning Santoni’s HT-50 and STAR-S models. The HT-50 is a single cylinder machine with single feed to produce heavy socks in terry, with four colours plus ground on the same course. There is also the possibility of knitted or laid-in elastic for a single or double welt or again a four-color pattern double welt with tuck stitch. Thanks to its high technological content, the HT-50 combines productivity and quality with extreme ease of use. On request is the automatic toe-closing SbyS device, which uses ‘true linking’ technology, resulting in a higher quality sock in terms of finishing, comfort and durability, compared to those produced with traditional methods.

The new STAR-S model is a single cylinder machine with single feed and needles in the dial, which produces high-quality socks in true rib, with five-colour patterns and knitted or laid-in elastic and sculptured terry. Heel and toe production uses a reciprocating movement, creating three-dimensional effects without the aid of pickers and positioning the heel anywhere on the sock. The knitting head of the machine is also equipped with cams and a Santoni patented special chain system which allows preselected needles to be driven to the exact working stitch cams.

Further information

- Mr. Valsecchi Gianpiero

+39 335 6824564

- Ms. Elena Antelmi

+39 348 2355819

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more