New dates for ITMA Asia + CITME 2018

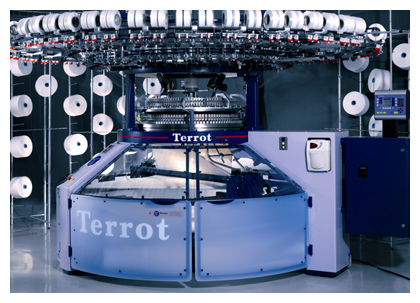

Perfect circular knitting technology combined with the "finest Terrot knitted fabrics" is the culmination of well-developed machine engineering designed to sharpen the competitive edge of our international customer base. The name Terrot stands for quality and top performance in the construction of electronically and mechanically controlled circular knitting machines around the world. Maximum efficiency and an outstanding cost-to-performance ratio, combined with t

29th May 2008

Knitting Industry

|

Chemnitz, Germany

Perfect circular knitting technology combined with the "finest Terrot knitted fabrics" is the culmination of well-developed machine engineering designed to sharpen the competitive edge of our international customer base.

The name Terrot stands for quality and top performance in the construction of electronically and mechanically controlled circular knitting machines around the world. Maximum efficiency and an outstanding cost-to-performance ratio, combined with truly universal application and operating convenience: These are the objectives at the forefront of our machine design and development work.

When he founded Terrot in 1862, Charles Terrot was laying the foundations for a great idea - an idea which has lost none of its validity to these days. The roots of the small easily manageable young company were firmly anchored in a foundation of quality, precision and customer orientation. The same firm foundation remains the solid basis for the internationally active corporation Terrot has become today.

When he founded Terrot in 1862, Charles Terrot was laying the foundations for a great idea - an idea which has lost none of its validity to these days. The roots of the small easily manageable young company were firmly anchored in a foundation of quality, precision and customer orientation. The same firm foundation remains the solid basis for the internationally active corporation Terrot has become today.

In 2006 the new owners of Terrot decided to move the headquarters to the location of its manufacturing Chemnitz. Thus the oldest manufacturer of Circular Knitting Machines operates now with 145 employees exclusively in Chemnitz.

Terrot is unique in its ability to rely on a team of seasoned and committed experts and to turn 146 years of tradition in the construction of knitting machines into innovative products which address the needs of today's marketplace. With developments for ever expanding fields of application and effective production to address market demands coupled with maximum customer acceptance.

An elaborate system of quality controls and the use of state-of-the-art electronic engineering help our customers to keep abreast of the headlong pace of market change. Our model range encompasses mechanically and electronically controlled single and double jersey circular knitting machines with a large range of different gauges and diameters. Terrot machines have proven their outstanding reliability in day-to-day production in knitting factories the world over. The machines are designed to be particularly user-friendly and easy to operate. All machine components are produced and assembled in compliance with the strictest standards of quality and process reliability. Each Terrot machine which leaves the factory is subjected to careful monitoring and complies with the very highest standards of GERMAN ENGINEERING at its best.

The high-quality knits produced are used in the field of fashion outerwear and underwear, functional sports and leisure wear and increasingly also for technical applications. Today, there is endless scope for imaginative design from the latest fashion outerwear through to high-tech textiles, backing material for coatings and roof linings for whole car series. It is not for nothing that some of the biggest brand names choose to manufacture their products on Terrot circular knitting machines. All Terrot customers are able to rely on an international network of dealers, Terrot branches and service centres.

Our commercial success and therefore also the success of our customers is determined largely by the success of our continuous improvement policy, service processes and internal procedures. The continuous improvement of our efficiency is an essential corporate objective, safeguarding our ability to address the needs of our customers as and when required.

The ITMA Asia fair is due to take place from the 27th to 31th of July this year in Shanghai. Terrot is among the exhibitors and would like to invite you to visit their booth No.C08, Hall E4 where they will exhibit 3 new designed and developed machines.

TERROT invented the striper technology for knitting machines in 1950. We will now introduce a 6-colour Single Jersey Striper with 4 cam tracks. While knitting large sequences in a single colour, the machine will automatically speed-up by about 25%, thereby increasing productivity. Thanks to this „Terrot Speed-up Function“ the speed of 27 rpm will be increased to around 32 rpm which results in a production output unknown from other striper machines in the market. The long tradition of TERROT as a leading manufacturer of high performance striper machines will thus be continued by this introduction. The unique Terrot technique with independent drapers and scissors will also guarantee unmatched security in yarn changing of all synthetic and spun yarn qualities.

TERROT invented the striper technology for knitting machines in 1950. We will now introduce a 6-colour Single Jersey Striper with 4 cam tracks. While knitting large sequences in a single colour, the machine will automatically speed-up by about 25%, thereby increasing productivity. Thanks to this „Terrot Speed-up Function“ the speed of 27 rpm will be increased to around 32 rpm which results in a production output unknown from other striper machines in the market. The long tradition of TERROT as a leading manufacturer of high performance striper machines will thus be continued by this introduction. The unique Terrot technique with independent drapers and scissors will also guarantee unmatched security in yarn changing of all synthetic and spun yarn qualities.

As early as 1999 in Paris TERROT was first to introduce a Single Jersey Circular Knitting machine where the tubular fabric was cut and wound-up in open condition directly in the machine. This improved new S296-1 is now available with a very compact open width frame which offers very easy handling by the operator. This innovative design was demanded by the market. The speed factor is 1050 (35 rpm in 30 inch).

As early as 1999 in Paris TERROT was first to introduce a Single Jersey Circular Knitting machine where the tubular fabric was cut and wound-up in open condition directly in the machine. This improved new S296-1 is now available with a very compact open width frame which offers very easy handling by the operator. This innovative design was demanded by the market. The speed factor is 1050 (35 rpm in 30 inch).

Most of the knitted fabrics for Mattress Ticking’s are at present produced by 38 inch machines with 60 feeders. With its new 90 feeders, this UCC572M will be in a class by itself with a productivity increase of 50% and around 30 kg/h production output. The 3-Way-Technique on all 90 feeders UCC572M permits an unlimited kind of applications such as Mesh, Spacer, Blister etc. The versatility of this UCC572 is unmatched in the market place.

Most of the knitted fabrics for Mattress Ticking’s are at present produced by 38 inch machines with 60 feeders. With its new 90 feeders, this UCC572M will be in a class by itself with a productivity increase of 50% and around 30 kg/h production output. The 3-Way-Technique on all 90 feeders UCC572M permits an unlimited kind of applications such as Mesh, Spacer, Blister etc. The versatility of this UCC572 is unmatched in the market place.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more