Terrot closes Italian subsidiary

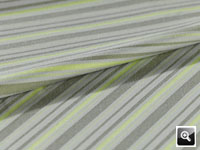

German circular knitting machine builder Terrot will show its latest technology for knitting striped fabrics at the forthcoming  ‘7th Dhaka International Textile and Garment Machinery Exhibition 2010’ (DTG 2010), which is being held from 2-5 February 2010 in Dhaka. Clothing is Bangladesh’s number one export with the fast growing readymade garment (RMG)sector accounting for more than 76% of total export earnings. The country is one of the top five RMG expor

12th January 2010

Knitting Industry

|

Chemnitz

German circular knitting machine builder Terrot will show its latest technology for knitting striped fabrics at the forthcoming ‘7th Dhaka International Textile and Garment Machinery Exhibition 2010’ (DTG 2010), which is being held from 2-5 February 2010 in Dhaka.

German circular knitting machine builder Terrot will show its latest technology for knitting striped fabrics at the forthcoming ‘7th Dhaka International Textile and Garment Machinery Exhibition 2010’ (DTG 2010), which is being held from 2-5 February 2010 in Dhaka.

Clothing is Bangladesh’s number one export with the fast growing readymade garment (RMG)sector accounting for more than 76% of total export earnings. The country is one of the top five RMG exporters in the world with annual exports of over US$ 7.50 billion and in 2010 this figure is expected to grow to US$ 10.00 billion. DTG 2010, which is the dedicated textile machinery exhibition for the region will host a wide range of textile machinery technologies and more than 600 local and international exhibitors from 30 countries will participate.

Terrot, which is jointly exhibiting with its partner Terrot Bangladesh will exhibit its S4F348 single striper machine. The company says that it’s single striper machines with 4 or 6 colour stripers and even with 4 needle tracks, provides decisive advantages in production and huge application variety.

The model on show in Dhaka will be a two track, 48 feed, 30 inch diameter machine in gauge E24 with a speed of 28 rpm or 32 rpm with Terrot’s speed up function.

Terrot says that the S4F348 combines the traditional attributes of functional safety and outstanding reliability with further improved Terrot striper technology. The benefit, it says, is maximum processing variety with nearly unlimited pattern and colour possibilities, especially for sensitive yarns, due to the combination of the Terrot Striper System with different kinds of structure techniques. By using its multi-colour technology, Terrot says it is possible to process up to 8 colours in a single length of fabric.

The company says that unsurpassed versatility includes the processing of even the most sensitive yarns. Besides the standard yarns such as cotton, the S4F348 can reliably process acetate, core spun yarns, Modal, polyester filament, polyamide and viscose. Yarn change is effected with one lay-in finger for every colour yarn. Each yarn lay-in finger is equipped with a combined clamping device as well as a cutting device which Terrot says guarantees very precise clamping and cutting of the yarns. The company adds that, unlike its competitors, with this striper technology its machines are able to process all yarn qualities, particularly for striped fabric in line with the current trends.

The S4F348 has a redesigned cylinder and sinker cam curves which permit safer production at an increased speed factor of 840 (S4F348/6F348). The machine also encompasses an economic production feature in its computer controlled ‘Terrot-speed-up-function’, whereby the machine speed increases by 20% while knitting large sequences in a single, thereby increasing productivity flexibility and versatility.

The S4F348 has a redesigned cylinder and sinker cam curves which permit safer production at an increased speed factor of 840 (S4F348/6F348). The machine also encompasses an economic production feature in its computer controlled ‘Terrot-speed-up-function’, whereby the machine speed increases by 20% while knitting large sequences in a single, thereby increasing productivity flexibility and versatility.

In addition, Terrot says the machine’s 2-slot yarn carrier is perfectly guided and guarantees excellent Spandex and Mesh plating. It also says that the S4F348 is easy to handle and new pattern information can be created by transmitting the colour sequence by USB memory stick. Simple and quick adjustment of colour sequences can be carried out by inputting the data via the terminal keypad.

Application areas for the S4F348 are outerwear and sports and leisure wear and the following fabric structure and knitting techniques are possible:

Striper pattern/ colour change striper, plain single jersey, elastane plaiting single structures, 2-thread fleece, piqué and tuck structures.

“Perfect circular knitting technology combined with the finest Terrot knitted fabrics is the culmination of well developed machine engineering designed to sharpen the competitive edge of our international customer base,” says Uta Barthel, Terrot’s Marketing & Communication Manager.

“The Terrot brand stands for quality and top performance in the construction of electronically and mechanically controlled circular knitting machines around the world. Maximum efficiency and an outstanding cost-top performance ratio, combined with truly universal application and operating convenience: These are the objectives at the forefront of our machine design and development work,” adds Ms. Barthel.

7th Dhaka Int’l Textile and Garment Machinery Exhibition 2010

B ICC, Bangabandhu International Conference Centre

Agargaon, Shere - Bangla Nagar, Dhaka, Bangladesh

2-5 February 2010

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more