-300x192-cropped.jpg)

New shoe fabric patterns with COP 5 M-EL

By leveraging digital technologies, HP, Decathlon and Lonati Group are defining the future of manufacturing.

15th June 2023

Knitting Industry

|

Milan

HP, a global technology leader, joined forces with the world’s largest sports goods retailer Decathlon, and Italy’s Lonati Group, to unveil a game-changing manufacturing concept at this week’s ITMA 2023 textile machinery show in Milan.

Together, the companies presented an innovative and sustainable approach to shoe manufacturing, that they say is set to reshape the industry. By harnessing the power of advanced technologies, including HP's Multi Jet Fusion technology and Lonati Group’s shoe-upper knitting machines, the collaboration paves the way for a future of sustainable footwear production.

Traditionally, shoe production requires numerous parts, adhesive materials, and a significant workforce. However, HP, Lonati Group and Decathlon are revolutionising the process by leveraging the power of 3D printing. In their latest innovation, the companies have developed a sports shoe that is said to embody the future of footwear manufacturing.

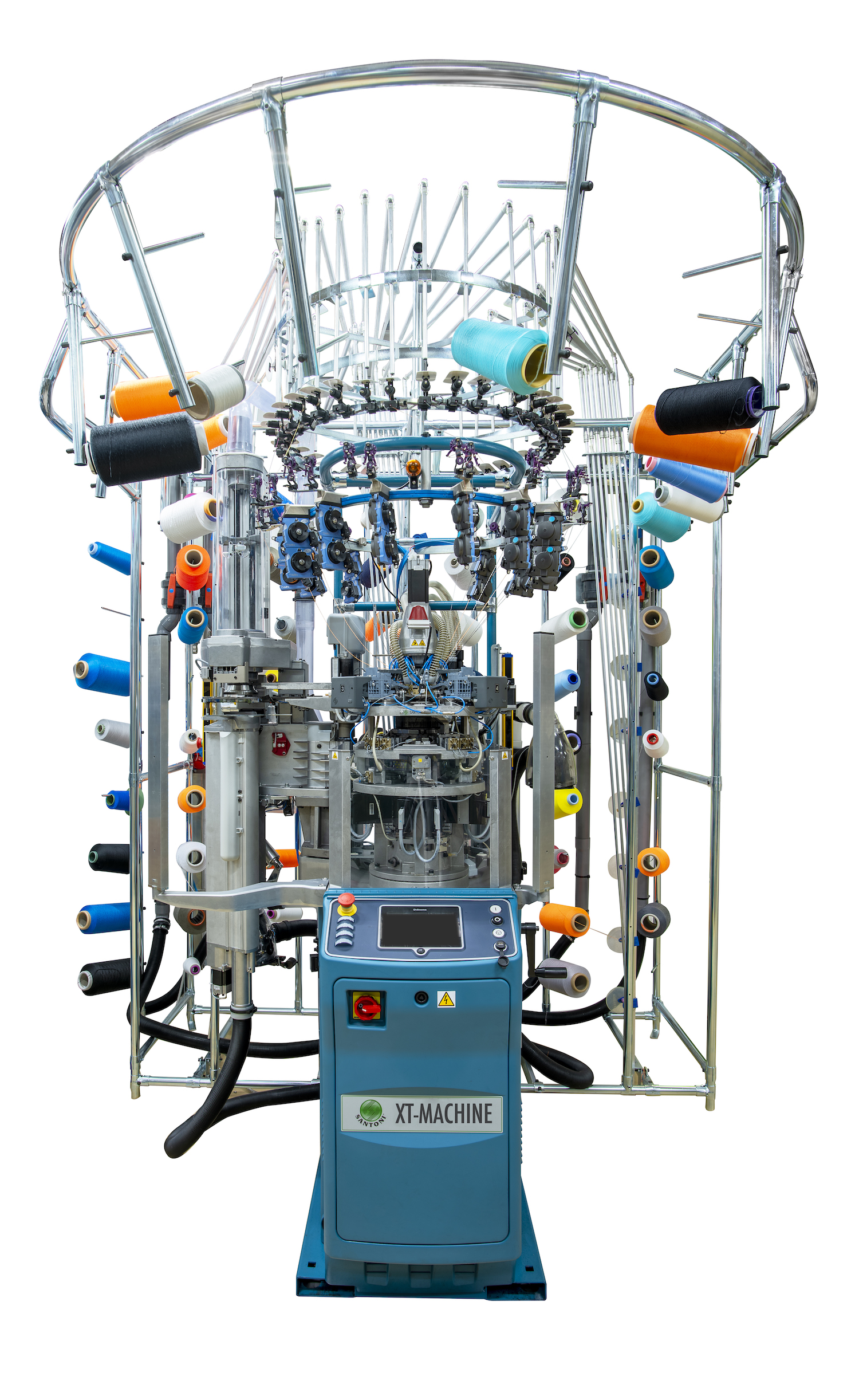

This ground-breaking shoe combines Lonati Group’s meticulously crafted sock with an innovative midsole and outsole produced using HP's state-of-the-art 3D printer. Specifically, Santoni’s XT-MACHINE and Lonati’s Double Cylinder E1530XS knitting machines allow the production of shoe uppers with single or double-layer fabrics, resulting in an integrated upper that offers unparalleled comfort, lightness, performance, and quality.

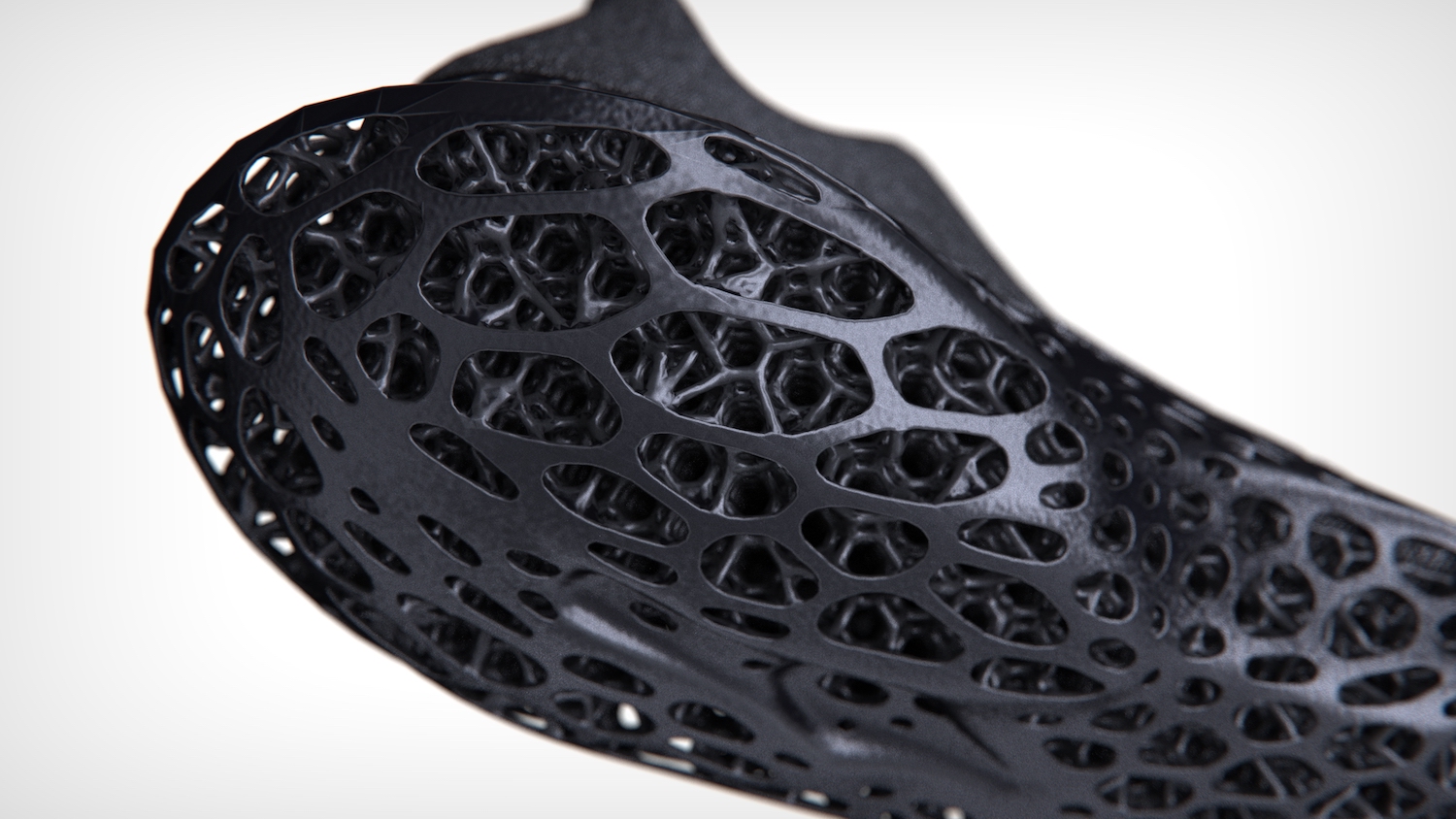

HP's Jet Fusion 5200 printer produces both the midsole and outsole of the shoe, showcasing the cutting-edge capabilities of 3D printing technology. To ensure optimal performance, the components are manufactured using BASF Ultrasint TPU01 material, a versatile thermoplastic polyurethane powder known for its exceptional shock absorption, and flexibility. By integrating these advanced materials and technologies, the partners are revolutionising the sports shoe industry, paving the way for innovative designs that deliver unmatched comfort, durability, and performance.

With the partnership, the companies want to share a main message, focusing on the advantages of 3D printing and digital knitting for manufacturing at an industrial level, emphasising the following key points:

- Customization: The shoe is highly customizable, enabling consumers to personalize their footwear to suit their preferences and needs.

- Circularity and Reparability: By utilizing a glue-free assembly method, the shoe can be easily repaired when damaged. The cushion and upper parts can be separated, allowing for targeted repairs without the need to discard the entire shoe. This not only extends the lifespan of the product but also reduces waste. Moreover, the use of a single material, TPU (thermoplastic polyurethane), for the grip and cushion parts enhances the shoe's recyclability. All of this contributes to a more sustainable and environmentally friendly product life cycle.

- Local Production: By leveraging 3D printing, the shoe can be produced locally, reducing transportation emissions, and supporting local economies.

- Flexibility: The manufacturing process allows for stock lifetime optimization and enables on-demand production and thus reducing waste.

Phillipe Seille, Exploration Leader at Decathlon, expressed his excitement about the collaboration, stating that: "We are thrilled to collaborate with HP's Personalization & 3D Printing business and Lonati Group on this project that exemplifies our commitment to sustainability. By leveraging the potential of 3D printing, we are revolutionizing the shoe manufacturing process, offering consumers customized, recyclable, and locally produced footwear."

Don Albert, Head of Footwear and Sports at HP Personalization & 3D Printing, added: "HP's Multi Jet Fusion Technology is enabling a new era of sustainable and innovative manufacturing. We are proud to partner with Decathlon in showcasing the immense potential of 3D printing in contributing to a more sustainable approach to manufacturing. Lonati Group's expertise in shoe-upper technology aligns perfectly with our shared values of sustainability. It is truly inspiring to work together."

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more