Karl Mayer expands its training offer

Karl Mayer says its customers not only benefit from its high-tech machines - the company's know-how and expertise can also give them the edge over their competitors. Warp knitted fabric manufacturers can win leading market positions and tap into new applications using efficient high-speed tricot machines and raschel machines, and the opportunities offered by the Karl Mayer Academy to learn more about them are available to textile manufacturers worl

11th January 2012

Knitting Industry

|

Changzhou & Obertshausen

Warp knitted fabric manufacturers can win leading market positions and tap into new applications using efficient high-speed tricot machines and raschel machines, and the opportunities offered by the Karl Mayer Academy to learn more about them are available to textile manufacturers worldwide.

The company's Training Centre runs its own training programmes at its headquarters in Obertshausen and at its subsidiary in Changzhou. The instructors at both locations work closely with each other, and this enables them to take into account the special regional requirements of customers in the main markets.

Just recently, a comprehensive training programme was held at Karl Mayer (China) Ltd., which was attended by the Karl Mayer's product developer, Stefan Gross and the instructor, Stephan Jung. The two specialists travelled from Germany to hold a series of courses on the RSJ range of machines and the RD 7 EL double needlebar raschel machine.

The courses on the RSJ machine were held from 17 to 26 October at the Karl Mayer Academy in Changzhou with the programme consisting of three training courses, each lasting three days, and providing information at different levels of detail.

There were between six and eight participants on each training course and the course mainly attracted designers who had already had experience with using the RSJ machines. The aim of the course was to provide them with the necessary expertise to develop more intricate patterns, to open up untapped markets, and to enable them to optimise the potential of the versatile RSJ machines.

Karl Mayer says standard fabrics, such as Powernet, can be produced on the majority of machines currently available on the market, but the options can be extended by working new, more sophisticated designs.

The possibilities of producing more fashionable fabrics, such as lightweight Spotnet fabrics with attractive, lace-like patterns and functional lingerie fabrics with body-shaping zones should guarantee long-term capital utilization and good business - concepts that newcomers to this sector are also finding particularly attractive, Karl Mayer says.

As well as companies who had already had some experience of the machines, companies who were beginning to take a general interest in the RSJ machines also registered for the course.

Basically, the course involved presenting the range of machines and highlighting the differences between the various models, explaining the jacquard principles, and developing basic lapping and design parameters based on these principles.

The experienced pattern developers were particularly interested in the performance features of the software and its latest upgrade. "High-end designs can be developed much easier and quicker using the latest functions. The edges of the motifs in particular have an incredibly smooth appearance," said one of the course participants enthusiastically.

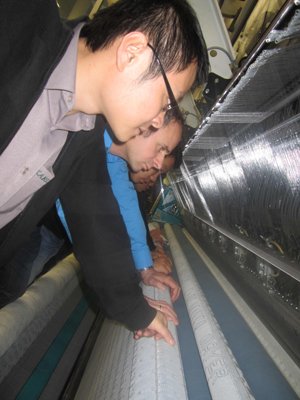

The theoretical part was followed by the practical part, which involved drafting various patterns and producing them on an RSJ 5/1 EL in the Training Centre. "As the machine was running, the advantages of using the individual functions, such as lapping changeover, the Multi-Speed function, and control of the fabric take-down to produce stitches of different size, became clear immediately - an invaluable learning experience for all the participants in the RSJ course, who were delighted with the course content," says Karl Mayer.

"The Chinese designers and textile specialists developed many new ideas for generating future business and collected useful tips that would be invaluable to them in their day-to-day work."

They were also given the opportunity to discuss production problems with the head of the course, Stefan Gross, and develop new ideas.

The two part training course on the RD 7 EL was held a month after the RSJ course. The first part took place from 14 to 19 November and covered the construction of the 3D fabrics produced on the double-bar Raschel machine. It was aimed primarily at designers and product developers.

The second part of the course was held from 21 to 26 November, when the instructor, Stephan Jung described the technical features of the machine and the sequences involved in producing the various patterns, using the machine available on site.

One of the main aspects covered in the course concerned the relationships between the construction of the pile spacer layer and important textile parameters such as thickness, weight per unit area, and compression resistance. Other topics covered included the quality of the warp-knitted spacer fabrics and especially the design potential offered by the RD 7 EL.

The specific configuration of the double-bar raschel machine in the Karl Mayer Academy (four patterning ground guide bars on the front needle bar, one pile bar, two stitch-forming ground guide bars on the rear needle bar and EL drive) offers a wide range of possibilities.

For example, the course participants learned how to create structured surfaces, different coloured effects, soft-touch constructions and mesh patterns having different opening widths. Karl Mayer says, particularly interesting was the production of different pore sizes, not only on the upper and lower surfaces, but also over the length and width of an area.

To consolidate what they had learned, the students used the ProcCad warpknit 3D system to simulate patterns and then produced them on a training machine. The RD course, which combined theory with practice, proved to be an extremely efficient and novel way of increasing the students' knowledge.

According to Karl Mayer, with their new-found knowledge, the participants returned home to breathe new life into the production of spacer textiles and thus to contribute to the success of their companies.

While the training courses were being held in China, training activities in the Academy in Obertshausen were continuing at full swing and if everything goes according to plan, roughly 220 participants will have attended courses on warp knitting by the end of the year.

Most of the courses focus on tricot machines. Basic courses (WKB) are available, which cover the basics of these versatile, efficient machines, and advanced courses are also available for more experienced users. Special training courses are also available for special applications.

Most of the people attending the courses are employees of the company's clients and they come from all over the world. They are able to benefit from a well-balanced mix of theoretical and practical instruction provided by a highly committed, experienced team of instructors in the Academy, which is equipped with all the latest machinery and equipment.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more