New needle selection technology from Terrot

Experience Makes the Difference' - was the slogan under which German circular knitting machine builder Terrot presented its latest machinery range at the 16th ITMA, the world's leading textile machinery exhibition Barcelona, Spain in September. ITMA 2011 featured exhibits from the entire textile and garment making value-chain spread over 200,000 square metres of total exhibition space and Terrot says it enjoyed a very successful exhibition. Â "ITMA 2011 has surpasse

28th November 2011

Knitting Industry

|

Chemnitz

‘Experience Makes the Difference' - was the slogan under which German circular knitting machine builder Terrot presented its latest machinery range at the 16th ITMA, the world's leading textile machinery exhibition Barcelona, Spain in September.

‘Experience Makes the Difference' - was the slogan under which German circular knitting machine builder Terrot presented its latest machinery range at the 16th ITMA, the world's leading textile machinery exhibition Barcelona, Spain in September.

ITMA 2011 featured exhibits from the entire textile and garment making value-chain spread over 200,000 square metres of total exhibition space and Terrot says it enjoyed a very successful exhibition.

"ITMA 2011 has surpassed our highest expectations. The presented exhibition machines corresponded in the best way to the actually market requirements and the present customer demands," said Andreas von Bismarck, Managing Partner of Terrot.

Terrot in fact introduced no fewer than six new and redeveloped circular knitting machines from its current product range in Barcelona.

The S296-2 is said to offer outstanding flexibility and efficiency in the production of different stitch structures with up to 4 needle tracks. Terrot says its ideal distribution of 102 feeds over 32" diameter is proven in practical day-to-day operation.

Striper Technology in Single-Jersey has already a very long tradition at Terrot - up to 6 colours striping in addition with the combination of 3-way-technique and the new fine gauge E36 development, which aims to open new trends in fashion.

Terrot says the stringent standard of quality and reliability of Terrot machines reaches its pinnacle with its Jacquard machine series. The ceramic PIEZO selection elements form the electronic-mechanical interface which reliably implements the knitting information even with extremely fine machine gauge at high speeds.

The production of transfer fabrics on the latest developed Electronic-Jacquard machine UCC572-T is said to offer highest production output at utmost efficiency.

Terrot's latest developed Mini-Jacquard model UP592M stands out by its appliance in the cost-efficient production of Mini-Jacquard mattress ticking. The combination of a high number of feeders and machine speed allows a never before achieved production output, Terrot claims.

This latest development of the 8-lock model I3P284-1 in fine gauges E40 - E50 offers a wider range in knitting structures, allowing rib and Interlock stitch formations to be combined for new fabric structures. "Terrot circular knitting machines are especially developed with respect to the market demands energy efficiency and performance. For example the exhibition machines showed an increase in efficiency up to 50%," Terrot reiterates.

New dimension in fabric knitting

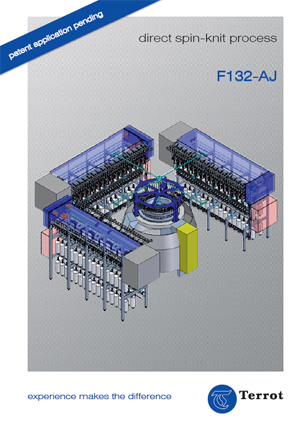

New dimension in fabric knittingTerrot's senior technical specialists also presented a future-oriented innovation to an exclusive audience at ITMA. The company's new F132-AJ direct spin-knit process was launched, which the company says is a new dimension in fabric knitting The Terrot F132-AJ direct spin-knit process uses an air jet spinning system. It does not mount the rovings, clearing or drafting units or indeed spinning nozzles on the knitting machine like competitors machines but instead it has a creel type arrangement on three sides of the machine which house the complete rovings to spinning process.

In other words, yarns are spun by the side of the machine and then fed to it in a more "normal" way. The F132-AJ spinning unit can be fitted to all Terrot Single-Jersey and Double-Jersey machines. Terrot says, the direct spin-knit system is even suitable for high system densities and large diameters (up to 120 feeders) and can be used in gauges from E20 - E36.

The spinning system, which is modular can be fitted with 24, 32 or 40 spinning heads per unit and has an integrated flyer, integrated fluff removal and integrated monitoring process. The fabrics are said to have a top quality feel and look, a soft handle and good dyeability with rich colours. Elastane plaiting is also possible with the new Terrot system. The F132-AJ has a speed factor of up to 600 (20rpm, 30") and unfinished fabric output of up to 360kg/24 hours (20rpm, 30").

Terrot says the new process offers remarkable customer's benefits with respect to:

·33% - 40% less required space

·up to 50% energy savings

·up to 30% less investment costs

·up to 50% less production costs

"Terrot is one of the leading manufacturers of electronically and mechanically controlled circular knitting machines worldwide. It even defends its position in the development and production of specialized machines and is counted among the most important members of the group Schüring & Andreas," the company says.

"Terrot strategic orientation of the company combines its traditional values like superior quality, innovative engineering solutions and consequent customer orientation with the demands of the global markets. With the know-how of 150 years experience and its innovations Terrot has made fundamental contributions to the development of the worldwide textile industry."

205 employees develop and produce innovative products and support the manufacturing site in Chemnitz with customized services.

"With more than 50 global cooperating representatives, own subsidiaries and service centres Terrot supports its customers with a market-oriented portfolio and comprehensive know-how to create the best solutions for your commercial and technical challenges," Terrot adds.

"The focus on trendsetting technologies, highest quality, flexibility, a long-term oriented portfolio and finance strategy and the defined objective to become a worldwide leading manufacturer of circular knitting machines, Terrot will further expand," the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more