Steiger introduces economical, high-performance machine in Europe

The management of the design, sampling and production of small quantities of high value-added knitwear is the new challenge of all knitwear manufacturers and is at the heart of their future performance. This is why Yxendis, a well known 3D knit creation and simulation software company and flat knitting machine builder Steiger have entered into a close partnership to deliver new business opportunities to their customers. This is achiev

14th October 2008

Knitting Industry

|

Vionnaz, Switzerland and St Chamond, France

The management of the design, sampling and production of small quantities of high value-added knitwear is the new challenge of all knitwear manufacturers and is at the heart of their future performance. This is why Yxendis, a well known 3D knit creation and simulation software company and flat knitting machine builder Steiger have entered into a close partnership to deliver new business opportunities to their customers.

This is achieved by providing their customers with the opportunity to improve their collection and product offers by giving the design team the means to use all their creative potential, helping to speed up their collection time-to-market and by making dramatic savings in the cost of sampling.

According to Yxendis’ Eric Gianna, their software range lets designers create patterns and grading from scratch or from a dxf file from another software package and export to knitting motifs module. The shape can also be exported to be printed or cut or can be exported as a knit pattern with automatic calculation of fully-fashion rules for widening or narrowing for example.

Gianna told KnittingIndustry.com: “The good thing about our software is the unbelievable performance and it’s easy to use motifs module. Our new partnership with Steiger has opened up a great new area of collaboration between the pure designer and the technical designer. In the design mode, lots of tools can be used to easily and quickly turn a 16 million colour design into a dot by dot knit design. In addition, lots of specific dot by dot knit design tools can be used for the design of geometrics, advanced stripes, text and stamp tools.”

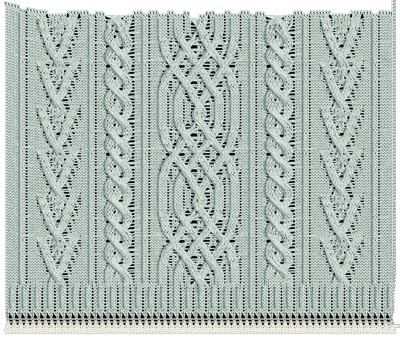

Other knit tools can also be used to apply knit structures such as laces and cables with the Knit structures symbols from the Steiger Model libraries or from self created Yxendis YX KNIT Platinium. The Steiger knit structures database can be shared on a network for instantaneous easy up-to-date management and the symbols can be seen as a real knit view or as a technical view. The final knitwear creation can be seen as a finished product for the pure designer or as a technical knit description for the technical designer.

Other knit tools can also be used to apply knit structures such as laces and cables with the Knit structures symbols from the Steiger Model libraries or from self created Yxendis YX KNIT Platinium. The Steiger knit structures database can be shared on a network for instantaneous easy up-to-date management and the symbols can be seen as a real knit view or as a technical view. The final knitwear creation can be seen as a finished product for the pure designer or as a technical knit description for the technical designer.

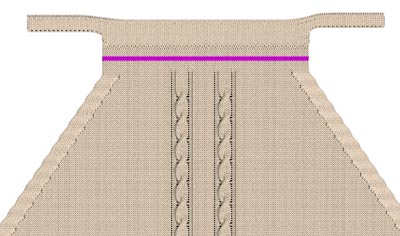

Users can work in a rectangular panel but also directly in the fabric pattern with two advantages. The first, is the ability to work directly in the different shapes (front, back, sleeves) so as to be able to adjust and adapt precisely each design for each shape in order to avoid the loss of time. The second advantage is to be able to work taking into account all the different sizes in order to have efficient design management and avoid unnecessary size adjustments later. Other functions are useful for the technician such as the automatic correction for narrowing and widening.

In the same way, final colourway choices (design and colourways) can be carried out by importing files from Steiger’s Model software to Yxendis in order to make colour tests and optimization with YX KNIT Platinium. Designs created with YX KNIT Platinium from Yxendis can also be exported to Steiger’s Model in order to go into sampling or production. Technical data can be printed for production and technical uses.

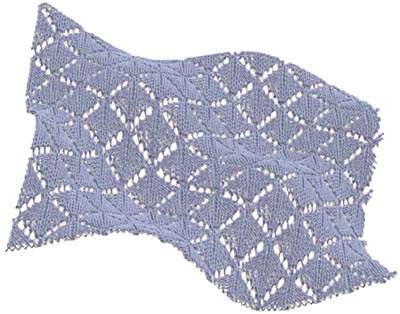

Yxendis’ real 3D simulation (real size) uses plain yarns as well as calibrated twisted, blended multi-count, space yarns. This yarn software is a complementary module which enablesto visualize lifelike finished knitwear in order to make colour changes and optimizations. Customizable prints can made in for show during internal or customer meetings. A direct link with the 3D mapping software enables fast mapping and test of new knitwear or colourways on images of models.

Yxendis’ real 3D simulation (real size) uses plain yarns as well as calibrated twisted, blended multi-count, space yarns. This yarn software is a complementary module which enablesto visualize lifelike finished knitwear in order to make colour changes and optimizations. Customizable prints can made in for show during internal or customer meetings. A direct link with the 3D mapping software enables fast mapping and test of new knitwear or colourways on images of models.

Yxendis claims that it has gone a step further than currently available colour calibration systems and has developed a unique and unequalled colour calibration and management system which enable printing of calibrated colourways without colour distortion. The company says that this is also a very effective way to speed up product simulation exchange for pre-validation of new products or colourways.

Steiger recently exhibited its latest machine offer, the Libra 3.130 at ITMA Asia + CITME in Shanghai and hosted a spectacular fashion show which highlighted elegant sweaters and dresses from its complete machine range.

Steiger recently exhibited its latest machine offer, the Libra 3.130 at ITMA Asia + CITME in Shanghai and hosted a spectacular fashion show which highlighted elegant sweaters and dresses from its complete machine range.

Steiger’s Managing Director, Pierre-Yves Bonvin says that the Libra 3.130 will continue the evolution of new Steiger developments for the modern needs of the knitting industry. “The compact machine dimensions for reduced floor-space requirement, offering highest production capacity such as flexibility, productivity and simplicity all combined with lowest energy consumption.” Said Bonvin.

At the core of the Libra 3.130 are motorised yarn carriers in the Steiger tradition to increase productivity but also to offer almost unlimited knitting possibilities which Steiger claim are simply impossible on other flat bed knitting machines.

The movements of the yarn carriers are independent of carriage movements and each single yarn carrier is freely programmable, automatically re-setting to its working position. The carriers can be moved forward or backwards along the axis of a knitting feeder, for better tucking and especially for better plating. Steiger says that it is very easy to produce weft insertion structures by advancing a yarn carrier to the front of the formation.

Steiger has improved with a new concept in the Libra with reduced dimensions and fast reverse time of the carriage. On the new Libra, the carriage no longer leaves the needlebeds and clamps at the end of the maximum stroke. The carriage has an integrated 3-system open cambox for direct yarn feeding for almost tensionless yarn supply, which Steiger claims gives the best stitch appearance for top quality knitwear.

Steiger has improved with a new concept in the Libra with reduced dimensions and fast reverse time of the carriage. On the new Libra, the carriage no longer leaves the needlebeds and clamps at the end of the maximum stroke. The carriage has an integrated 3-system open cambox for direct yarn feeding for almost tensionless yarn supply, which Steiger claims gives the best stitch appearance for top quality knitwear.

Steiger claims that, in true Steiger tradition the Libra is the simplest machine in its category with only one type of spring-less needle being used as with all other Steiger models. It also says that the Libra’s small needlebed with a depth of only 17 cm guarantees user friendliness and low cost maintenance. For programming the Libra, Steiger’s Model software is combined with the Yxendis design software, which the company says are very easy to learn with the Yxendis software giving huge savings in sampling costs.

Steiger says that the Libra is the ideal machine for knitting intarsia patterns, which can also be used to develop and create lots of other exciting new knitting and stitch possibilities. It thinks of the Libra as a new generation of machines which can open new markets which will bring greater benefits for its customers.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more