Textile Institute celebrates centenary with expansion drive

British textile machinery makers advance composites, fibres and testing technologies despite continued market uncertainty.

6th January 2026

Knitting Industry

|

Manchester, United Kingdom

Members of the British Textile Machinery Association have reflected on 2025 as a year of significant technological progress across technical textiles, digitalisation and materials testing, even as global markets remained volatile.

According to BTMA chief executive Jason Kent, the past year has seen members deliver new technologies for producing advanced fibres and fabrics, alongside the increasing integration of artificial intelligence and machine learning into process control systems. Major developments have also been recorded in materials testing, reinforcing the UK sector’s reputation for innovation. Looking ahead, Kent highlights strong momentum going into 2026, supported by participation in international exhibitions including JEC Composites in Paris and Techtextil in Frankfurt.

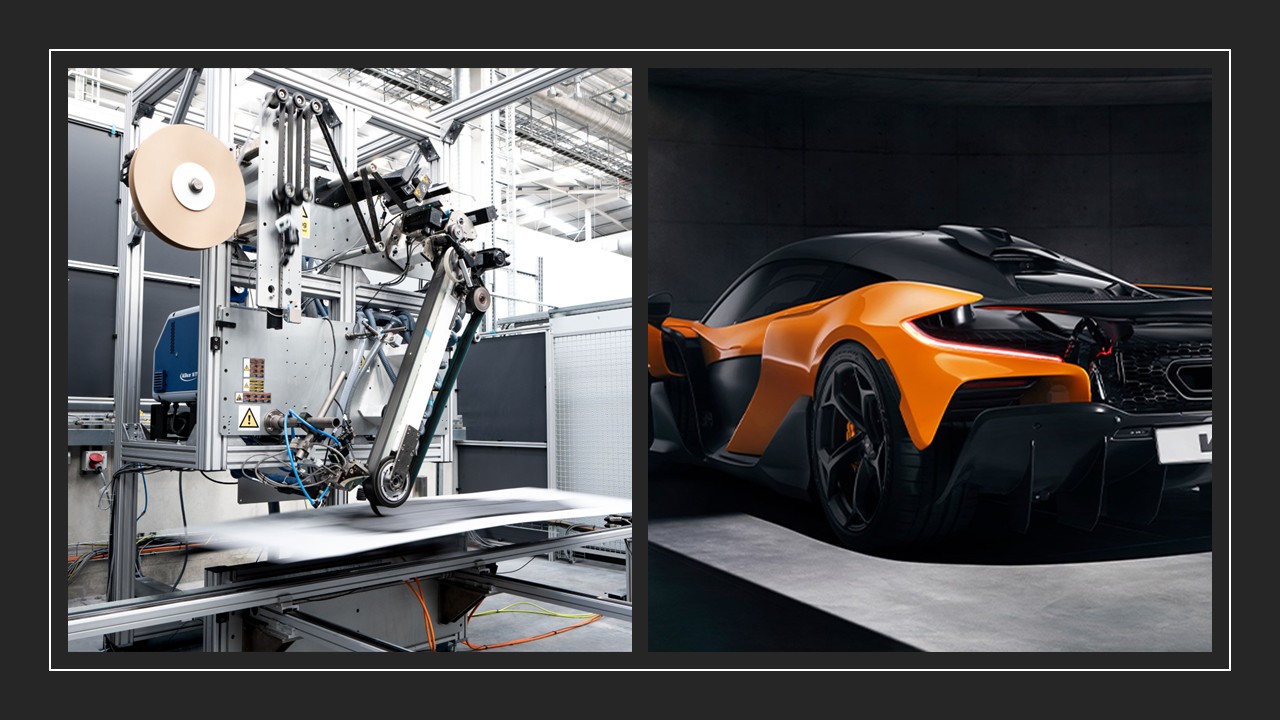

In the composites sector, Cygnet Texkimp has gained recognition through its nomination for a 2026 JEC Innovation Award, following its collaboration with McLaren Automotive on the ART rapid tape-deposition system. Designed to deposit dry fibre tapes at speeds of up to 2.5 metres per second, the system improves precision, reduces scrap and shortens cycle times, delivering measurable structural benefits in composite-intensive vehicle platforms. As the world’s largest independent manufacturer of prepreg production machinery, Cygnet Texkimp continues to expand its influence through handling, converting and recycling technologies, including its licensed manufacture of the DEECOM composite recycling system.

Other BTMA members are also supporting composite manufacturing, with Emerson & Renwick applying printing, forming and coating expertise to carbon fibre processing, Airbond advancing pneumatic yarn splicing for high-value fibres, and Slack & Parr supplying high-accuracy gear metering pumps for manmade fibre production.

In fibre processing, Fibre Extrusion Technology has introduced a new approach to manufacturing ultra-high molecular weight polyethylene. Its patented solvent extraction process, based on supercritical carbon dioxide, enables smaller-scale, more flexible gel spinning systems, addressing the complexity and inflexibility of traditional UHMWPE production.

Quality assurance and digitalisation remain key themes. Shelton Vision has extended the capabilities of its WebSpector automated inspection system, enabling reliable real-time defect detection on complex patterned fabrics, including those subject to distortion during processing. Applications now extend beyond automotive and airbags to fashion, performance wear, upholstery and even carbon fibre composites.

A similar move towards continuous monitoring is evident in colour management through the work of C-Tex, which has brought laboratory-grade colour measurement directly into production environments. By combining inline defect detection with continuous colour analysis, mills and downstream manufacturers gain greater transparency and confidence in fabric quality.

Advanced testing technologies continue to evolve, with James Heal introducing new performance testing solutions focused on speed, efficiency and ease of use, including improved water repellency testing and the flexible Martindale Motion abrasion system. Colour accuracy is further supported by the VeriVide DigiEye system, offering non-contact measurement and enhanced digital imaging.

Addressing the long-standing challenge of objectively assessing fabric feel, Roaches International has launched the Sentire fabric handle tester. The system allows manufacturers to quantify tactile properties such as softness, smoothness and drape, improving communication across global supply chains.

Bringing these developments together, Kent sees a clear convergence of advanced machinery, intelligent software and rigorous testing across the BTMA membership. He believes these innovations are laying the foundations for a more transparent, efficient and resilient textile manufacturing sector, supporting confidence in the future of British textile machinery on the global stage.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more