Lutz Wolf appointed Karl Mayer CEO

Electronic textiles pioneer Professor Tilak Dias calls it a day after a shining 40-year academic career.

19th October 2022

Knitting Industry

|

Nottingham, United Kingdom

Tilak Dias’ academic career began when he joined the University of Moratuwa, Sri Lanka, as an Assistant Lecturer in Knitting Technology after obtaining a ‘Diplom-Ingenieur’ degree in Textile Engineering with Summa Cum Laude from the Technische Universität in Dresden in 1981. In 1988 he obtained a ‘Dr.-Ingenieur’ also in Textile Engineering with Magna Cum Laude from the Universität Stuttgart.

World class research

After serving the University of Moratuwa for more than a decade, Tilak joined the Department of Textiles at UMIST (University of Manchester Institute of Science and Technology, now the University of Manchester) in 1992, with the vision of carrying out world class research with experienced technologists and researchers working at the cutting edge of knitting system research.

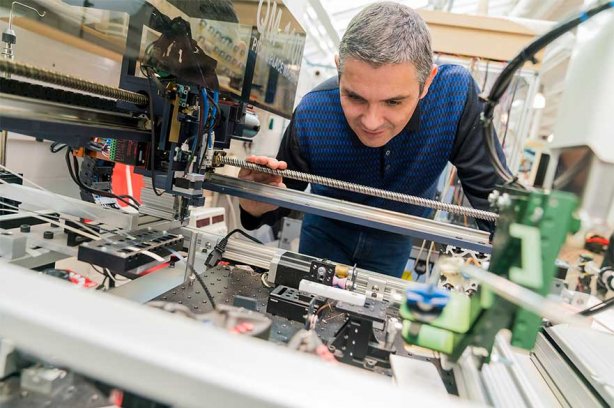

In the early years of his tenure at UMIST Tilak focused his research in the area of quality control and assurance of the knitting process; his PhD research at the Institut fὕr Textil- und Verfahrenstechnik (ITV) Denkendorf was the impetus for this line of research which resulted in the development of microprocessor based intelligent yarn delivery systems to control the stitch length of fabrics produced on computerised flat-bed knitting machines and circular knitting machines with a very high degree of precision.

Engineered medical textiles

The integration of mechatronic systems with flat-bed knitting machines revolutionised weft knitting technology, where the needles, stitch cam settings, fabric take-down and needle bed racking are very precisely controlled using microprocessors. This technology was first introduced by the machine manufacturer Stoll GmbH for the knitwear industry to improve the patterning and shaping efficiency.

However, Tilak realised as early as 1990 the potential of this technology as a tool for creating complex seamless-shaped 3D shell structures and shaped spacer structures for non-fashion applications, and decided to utilise this technology as the platform for developing a new research area of knitted medical textiles, engineered to a predetermined functionality, e.g. medical products/devices three dimensionally shaped to conform to the patient’s medical needs, by fusing flat-bed knitting and 3D body scanning technologies.

Electronic textiles

In 2002 Tilak widened his research into integrating electronics with textiles and is the most established academic in the UK to be engaged in this line of research. His research at UMIST resulted in a number of ground-breaking inventions - the bespoke compression hosiery Scan2Knit technology in 2002 (commercialised by Advanced Therapeutic Materials Ltd.) and the technology to produce seamless three dimensionally shaped shoe uppers in 2004, with his colleague William Hurley, which resulted in the now world-famous Nike ‘FlyKnit’. A spinout company SmartLife Technology was also formed by UMIST to exploit Tilak’s research on knitted electrodes, conductive pathways, and stretch sensors.

Professor of Knitting

Tilak subsequently joined the Nottingham Trent University (NTU) in 2010 as Professor of Knitting and formed the Advanced Textiles Research Group (ATRG) within the Nottingham School of Art and Design in 2011, to continue his research vision on advanced knitted structures and electronic textiles.

The perception of Tilak’s title, the Professor of Knitting, which is one being a craft-based activity, is very different to some of the research he has undertaken, such as developing unfurable metal meshes for satellite technology - Using Advanced Textiles to Enhance UK-based Technology and Manufacturing Capability in the US Dominated Space Satellite Telecommunication Industry.

During the final phase of his academic career at NTU Tilak invented a technology to integrate semiconductor micro devices within the fibres of yarns to produce smart E-textiles.

Tilak has supervised 25 PhD and 5 MPhil completions and has been named as an inventor on 80 patents. His research has resulted in three United Kingdom based university spin-out companies, and he has given over 60 invited talks. Tilak also edited the first book on E-Textiles and has authored over 180 scientific papers for leading international research journals and conferences.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more