Karl Mayer acquires YTC yarn tensioner technology

Family-owned circular knitting machine pioneer marks major milestone.

4th July 2025

Knitting Industry

|

Albstadt, Baden-Württemberg, Germany

On 8 July 2025, Mayer & Cie. will proudly celebrate its 120th anniversary, marking more than a century of innovation, craftsmanship and family leadership in the production of circular knitting and braiding machines. Headquartered in Albstadt, the company is now run by the fourth generation of the Mayer family and remains one of the textile industry’s most recognised names, with its signature green MCT logo seen on machines in knitting mills around the world.

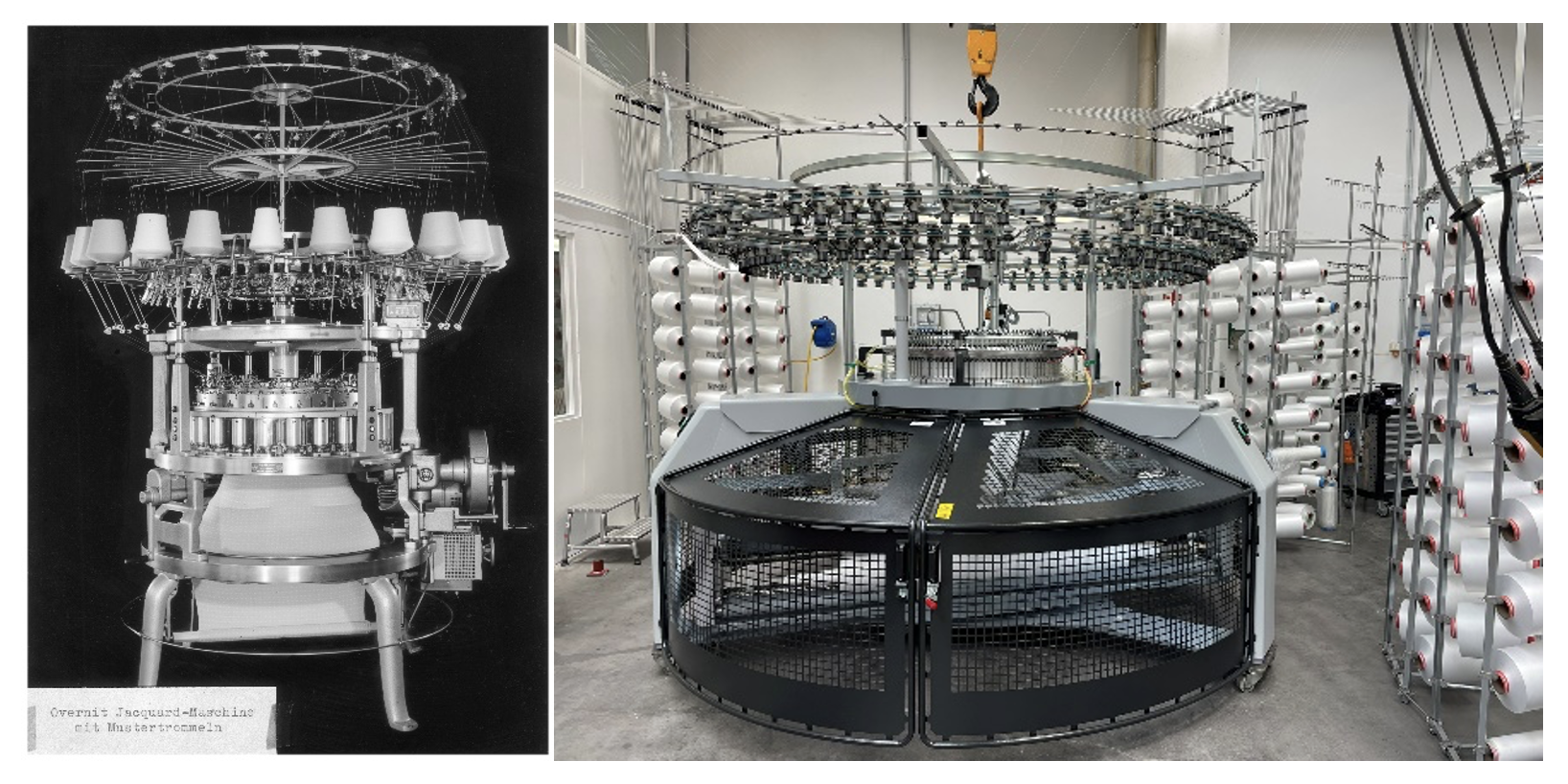

Founded in 1905, Mayer & Cie. has grown from a small regional business into a global leader, exporting almost all its machines and setting new standards with technical milestones that have shaped the history of circular knitting. From the first proprietary machines developed in the 1930s to the introduction of electronic pattern control in the 1970s and the game-changing Relanit series of the 1980s, the company has continuously pushed the boundaries of what is possible in knit production.

“Our 120th anniversary is something we’re incredibly proud of,” says Benjamin Mayer, Managing Partner and fourth-generation family member. “Statistics show that only about 12 percent of family businesses make it past three generations, and we are already in our fourth. It shows that we have consistently understood the market and met its demands with technological innovation.”

Today, digitalisation is at the core of Mayer & Cie.’s development strategy. The company recently launched a new machine control system that makes its circular knitting machines “IoT-ready”, enabling connection to the Internet of Things. This innovation allows customers to use knitlink, a digital platform offering various applications to monitor machine performance, access production data, and even conduct remote maintenance. This digital leap is designed to improve efficiency and reduce costly downtime — vital when a single circular knitting machine can produce around 2.5 metres of fabric every minute.

Another area of focus is sustainability and longevity. With new upgrade kits, customers can modernise their existing machines without having to purchase entirely new units, supporting investment security and machine lifespan. A new visual monitoring tool also ensures higher quality output, detecting fabric errors before they result in expensive waste.

Beyond circular knitting, Mayer & Cie. has expanded its braiding machine portfolio in recent years. Just before Christmas 2024, the company delivered its first braiding machine equipped with 48 carriers, with a second model now in development. This configuration enables larger inner hose diameters while maintaining high bobbin capacity and reducing setup times — crucial for industries such as manufacturing, mining and high-pressure hose production. Since 2019, braiding machine production has been relocated to Albstadt, reinforcing research and development capabilities.

Despite its proud anniversary, the company is realistic about the challenges facing the wider textile machinery sector. Like many manufacturers, Mayer & Cie. is navigating difficult global market conditions and expects lower volumes through 2026. The company has responded by reducing costs and securing the commitment of its workforce to weather the downturn. “We’ve lived through many crises since 1905,” says Mayer. “But the one we’re facing today is by far the most challenging.”

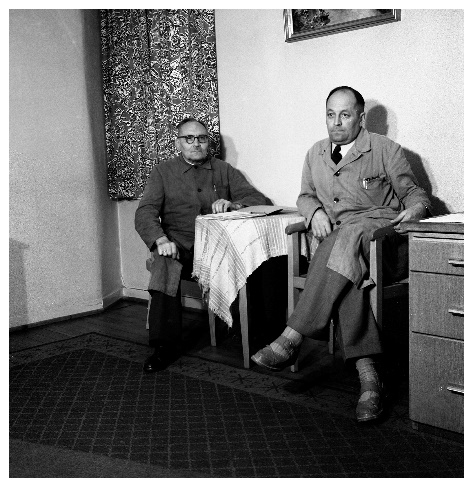

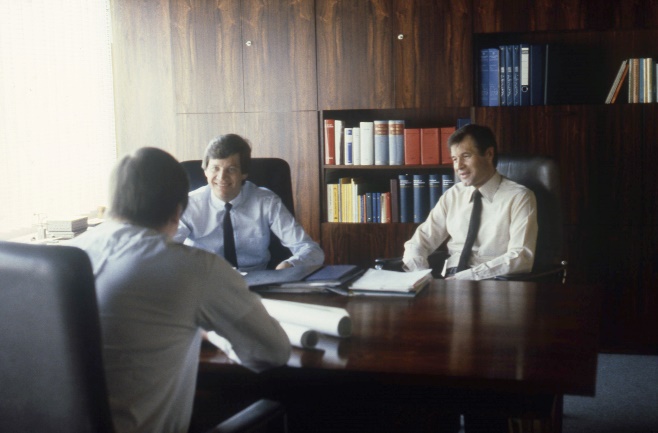

Throughout its history, Mayer & Cie. has remained resilient thanks to its commitment to engineering excellence and family stewardship. Johannes Mayer, one of the company’s original founders, was a master tinkerer who shaped the first circular knitting machines in the 1930s. His son Emil Mayer expanded the business globally after World War II and supported the local community by founding a textile school. The third generation, brothers Peter and Rainer Mayer, oversaw internationalisation, the adoption of electronics, and the revolutionary Relanit machine. Rainer, who co-led the company until 2015, also guided Mayer & Cie. through insolvency in 2009, emerging stronger and more focused than ever.

Today, brothers Benjamin, Marcus and Sebastian Mayer continue this legacy, jointly managing the company’s different business areas. With around 350 employees worldwide - 300 of whom are based in Albstadt - and representation in some 80 countries, Mayer & Cie. remains a trusted name in knitting technology. From home textiles and sportswear to technical textiles and reinforced industrial hoses, the company’s machines continue to meet the diverse needs of modern textile manufacturing.

As Mayer & Cie. looks ahead to its next chapter, its focus on digitalisation, sustainability and quality engineering will be vital in navigating an uncertain global economy. And for the global knitting community, the green MCT logo will remain a mark of German precision and a commitment to innovation that has endured for 120 years - and counting.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more